The Benefits of Partnering with a Quality Dip Molding Firm

Partnering with a quality dip molding firm can make quite a bit of difference in your chances of success as a business. Dip molding is a versatile and effective plastic manufacturing process, but to get the most out of it, you need to work with a company that has experience, precision, and a track record […]

Why Air Tools Need Dip Molded Protective Covers

Air tools are widely used in the automotive, construction, and manufacturing industries. While they’re essential in helping thousands of workers get the job done each day, they can take on a lot of wear and tear. So, it makes sense that these tools would need some extra protection to ensure they last longer, stay in […]

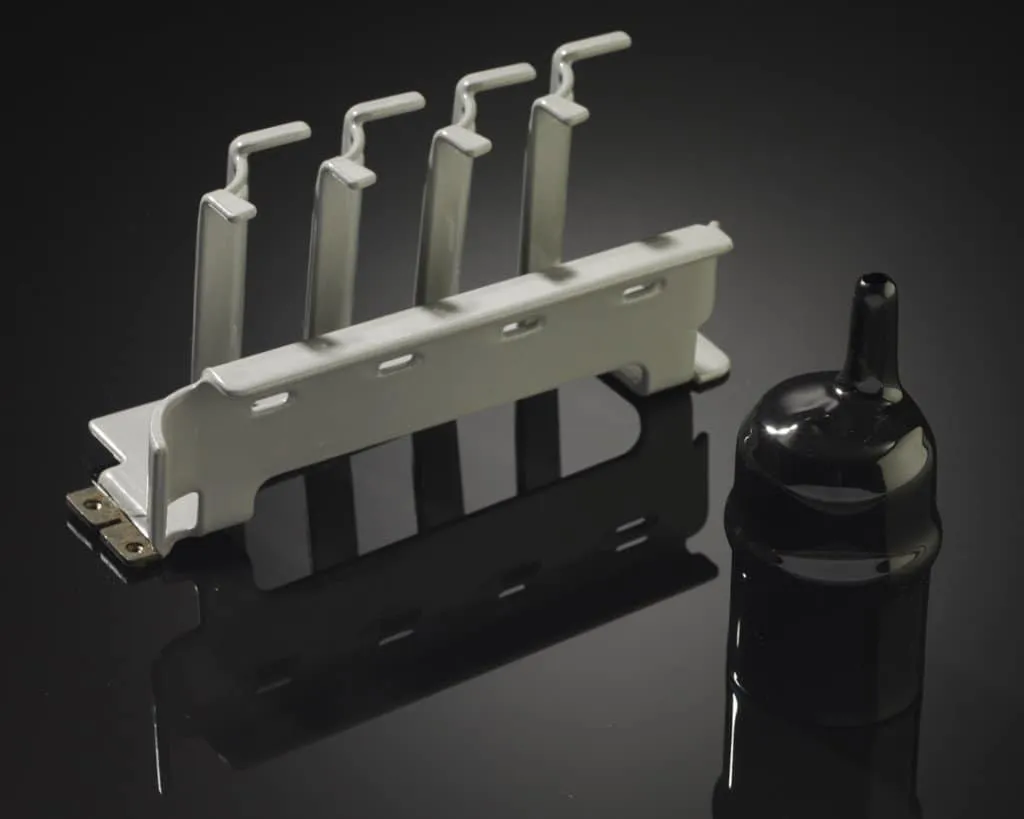

How Dip Molding and Coating Can Be Used to Protect Electrical Products

Electricity is vital to basically every aspect of modern life, meaning that electrical products and components are vital to our lifestyles as well. Those components becoming damaged or being destroyed would be, at best, a major inconvenience and, at worst, a catastrophe. So, what protects our important electrical products and components? Plastic products that are […]

How Dip Molding and Coating Help a Variety of Professionals Get the Job Done

Every day, millions of people use precise and durable tools and products to assist them in doing a wide variety of tasks across many fields. It would not be possible for these people to do their jobs if not for the manufacturing processes that make these tools and products possible. For example, dip molding and […]

Why Spring-Reinforced Endotracheal Tubing Requires the Highest Quality Manufacturing

Everyone who runs a medical facility wants to provide only the highest level of care. When making any decision that will affect patient care, you should ask yourself what you would want if you or a loved one were being treated at your facility. With that in mind, it’s obviously important for all medical equipment […]

Dip Molded Products that Protect Other Products

The plastic manufacturing processes of dip molding and coating are so vital in creating many of the products we use each day. Today, let’s zoom in on one specific type of product made via these processes: those products that protect other products. Not sure what I’m referring to? Here are some examples: Caps and Tips […]

Examples of Dip Molding and Coating in the Food Service Industry

We all enjoy going to restaurants, bars, breweries, the like, but how often do we think about how various products in those industries are made? Probably not very often. Yet, plastic manufacturing processes like dip molding and coating are used to create and improve a variety of products that enhance your dinning experience. Here are […]

How ADA Compliant Plumbing Fittings are Made

ADA compliant plumbing fittings play a minor yet important role in the lives of many, but it’s likely that very few think about how they’re made or what their function is. The reality is they are key to ensuring accessibility, safety, and convenience for everyone, including those with disabilities. Here’s what you need to know […]

The Importance of Quality Moldings and Coatings for Cable Management Systems

Considering how many technological devices we keep in our homes and offices; cable management has become an important task. No one wants all their cords tangled up or causing clutter and chaos. Because of this, people have increasingly begun using cable management systems. However, these systems are only as good as the materials they’re made […]

Dip Molded Plastic Products that Can be Found in Your Home

Dip molding is a plastic manufacturing process that’s used to create a bevy of products and parts of products you can likely find in your home right now, providing convenience and functionality. Here are a few examples of the types of home products this process creates: What is Dip Molding? First, it’s important to understand […]