How Dip Coating Provides Durability to Military Items

Military tools and equipment have to stand up to the harshest of conditions from extreme temperatures to moisture, dirt, and chemical exposure. That’s where dip coating comes in, providing essential durability to military items. In this blog, we’ll cover how the process works and why it’s so important for military equipment. What is Dip Coating? […]

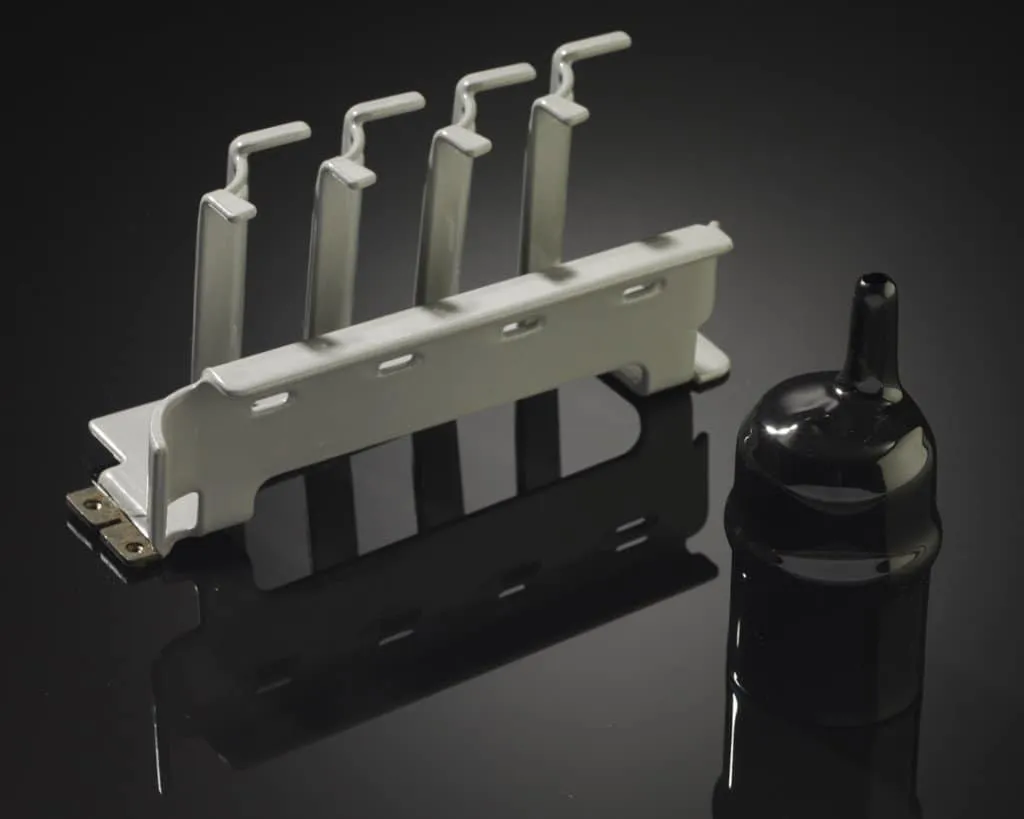

How Dip Molding and Coating Can Be Used to Protect Electrical Products

Electricity is vital to basically every aspect of modern life, meaning that electrical products and components are vital to our lifestyles as well. Those components becoming damaged or being destroyed would be, at best, a major inconvenience and, at worst, a catastrophe. So, what protects our important electrical products and components? Plastic products that are […]

How Medical Procedures are Aided by Dip Molded Products and Components

Every day, thousands of people undergo medical procedures ranging from the mundane to life and death levels of seriousness. Skilled surgeons and other medical professionals rely on certain tools to aid in these procedures. Many of those products are either made or enhanced by the plastic manufacturing processes of dip molding and dip coating. Here […]

How Dip Coating Can Play a Role in the Success of Military Operations

When it comes to the success of military operations, even the most minute detail is crucial. This means that something as simple as the quality of the plastisol coating on certain items can make or break an operation. You may not realize it, but the military relies on a myriad of tools and equipment that […]

Examples of Dip Molding and Coating in the Food Service Industry

We all enjoy going to restaurants, bars, breweries, the like, but how often do we think about how various products in those industries are made? Probably not very often. Yet, plastic manufacturing processes like dip molding and coating are used to create and improve a variety of products that enhance your dinning experience. Here are […]

How ADA Compliant Plumbing Fittings are Made

ADA compliant plumbing fittings play a minor yet important role in the lives of many, but it’s likely that very few think about how they’re made or what their function is. The reality is they are key to ensuring accessibility, safety, and convenience for everyone, including those with disabilities. Here’s what you need to know […]

The Importance of Quality Moldings and Coatings for Cable Management Systems

Considering how many technological devices we keep in our homes and offices; cable management has become an important task. No one wants all their cords tangled up or causing clutter and chaos. Because of this, people have increasingly begun using cable management systems. However, these systems are only as good as the materials they’re made […]

Why Plastisol Coated Military Items Must Meet Stringent Requirements

Not just anyone can manufacture items that are commonly used by the military. When it comes to items that have plastisol coatings, manufacturers must meet stringent requirements in order for the military to be able to use these items. There are quite a few reasons for this. So, let’s explore the reasons behind these rigorous […]

How Tools and Equipment are Improved by Dip Coating

Dip coating is an innovative process that can significantly enhance various tools and equipment. From improving grip and durability to adding protective layers, dip coating has transformed the way we interact with certain products. Here’s how dip coating is making a difference in the world of tools and equipment: What is Dip Coating? Before we […]

Enhancing Product Performance with Plastic Dip Coating

Plastic dip coating is used as a finishing touch when creating a variety of products, many of which you may use on a regular basis. This common technique can improve the performance of certain tools and other objects. Here’s how: What is Plastic Dip Coating? Plastic dip coating essentially gives your product a second skin, […]