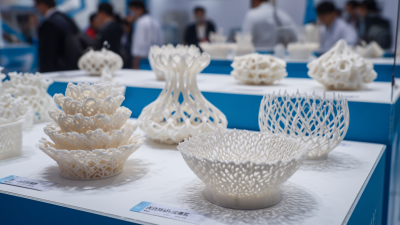

In the world of mold making, selecting the right materials is crucial for achieving high-quality results, and silicone rubber for mold making stands out as a premier choice. According to a recent industry report by Market Research Future, the global silicone rubber market is projected to reach approximately $8 billion by 2025, driven by its versatility and superior performance in various applications. Silicone rubber offers excellent flexibility, thermal stability, and resistance to environmental factors, making it ideal for creating detailed molds that can withstand repeated use. Moreover, a study by Technavio indicated that the demand for silicone rubber in the manufacturing sector is expected to grow at a compound annual growth rate (CAGR) of 6% through the next several years. As such, understanding how to choose the right silicone rubber for mold making not only enhances production efficiency but also ensures the durability and precision of the final products.

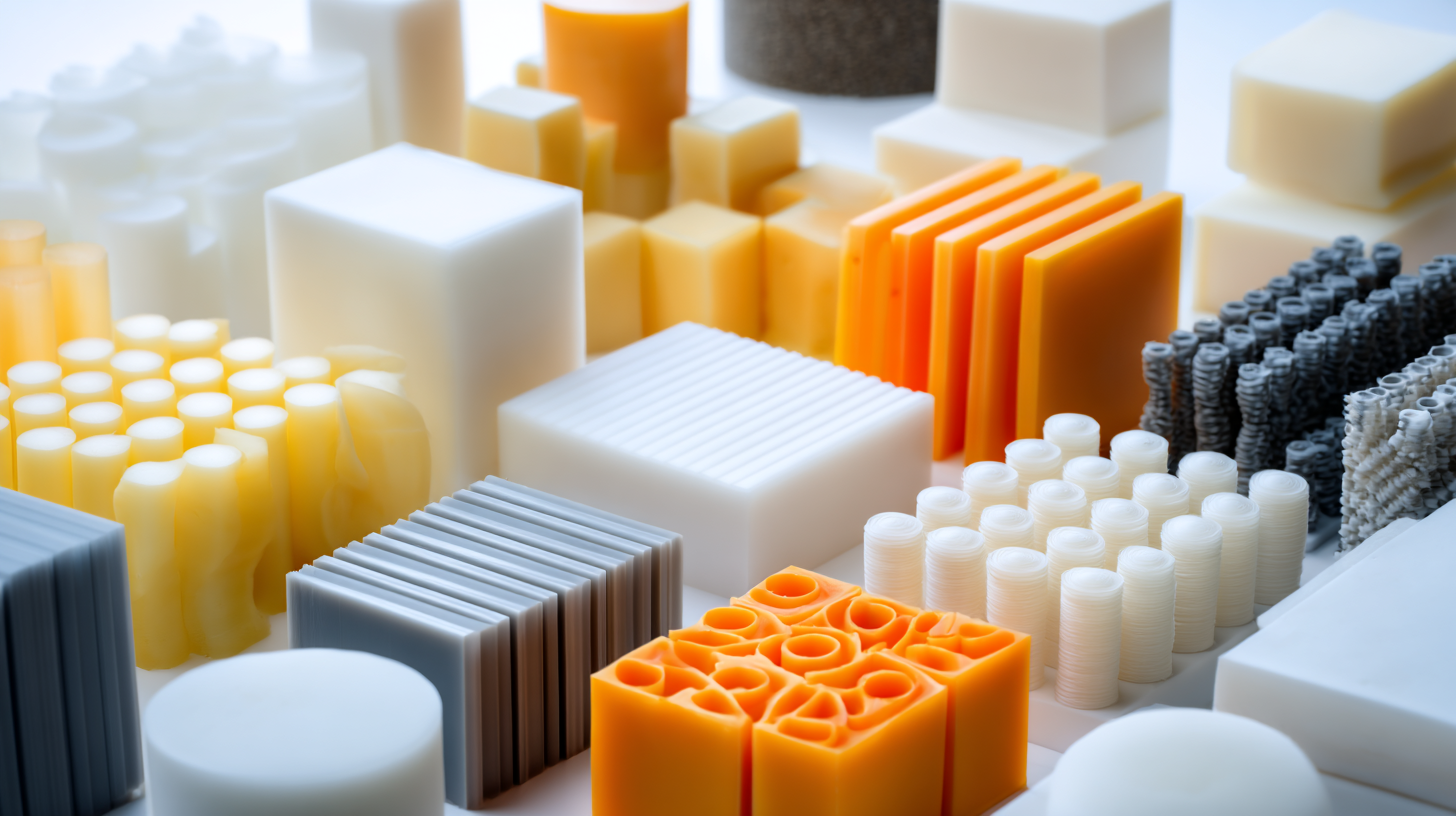

When it comes to choosing the right type of silicone rubber for mold making, several key attributes should be taken into account to ensure optimal results. One of the primary considerations is the formulation of the silicone itself. Silicone rubbers are typically characterized by their durometer, or hardness, which ranges from very soft to very hard. For detailed mold applications, a medium-hardness silicone, typically around 20 to 30 Shore A, is often preferred because it balances flexibility and strength, allowing for intricate details while still providing durability during demolding.

Another essential attribute is the silicone's tear resistance, which is critical for applications involving complex shapes or undercuts that may stress the mold during use. High tear strength silicones can endure the repeated stretching and pulling that occurs during the casting process. Furthermore, the temperature resistance of the silicone is also an important factor, particularly if the molds will be used for casting materials that generate heat during curing. Research indicates that silicone rubbers can sustain operational temperatures ranging from -50°C to 200°C, making them suitable for a variety of applications in both industrial and artistic endeavors.

Additionally, consider the curing time and method. Fast-curing silicones can significantly enhance productivity, while room temperature vulcanizing (RTV) silicones allow for easier use in various environments. According to industry standards, a suitable silicone rubber should offer a balance of these properties to fulfill specific project requirements, ensuring that the final product meets both technical specifications and performance expectations.

When selecting silicone rubber for mold making, understanding hardness ratings is crucial for achieving optimal performance. The durometer scale measures the hardness of materials, with most silicone rubbers falling between a rating of 10A to 80A. A lower durometer rating indicates softer silicone, which offers flexibility and ease in demolding intricate shapes, while higher ratings provide durability and resistance to wear. According to a 2022 market analysis by the Silicone Rubber Association, molds made from silicone with a durometer of 30A to 50A tend to exhibit an ideal balance of pliability and sturdiness, making them suitable for a wide range of applications.

Tip: When selecting silicone rubber, consider the specific details of your project and the complexity of the molds involved. For highly detailed designs, a softer silicone (around 20A-30A) may be beneficial, while for more substantial, less intricate designs, a harder silicone (50A-70A) can ensure longevity and support.

Moreover, different industries may require varying hardness levels based on their processes. For instance, the automotive industry often utilizes silicone rubbers with a durometer of 60A to 70A due to their resilience against high temperatures and harsh conditions. Conversely, the art and craft sectors may favor softer varieties for their capabilities in capturing fine details in designs. Always keep the intended use of the molds in mind to select the most effective durometer rating.

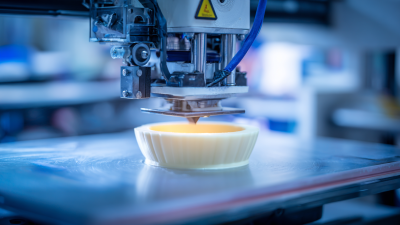

When evaluating curing methods for silicone rubber in mold making, it’s essential to understand the different options available and their suitability for various applications. The most common curing methods include heat curing, room temperature vulcanization (RTV), and platinum-cure silicone. Each method has its own advantages; for instance, heat curing often accelerates the curing process, making it ideal for larger production runs, while RTV allows for greater flexibility in the molding process for complex shapes.

Tips: When using heat curing, ensure that the silicone is compatible with your mold materials to avoid any adverse reactions. For RTV silicones, temperature and humidity can significantly impact curing times; always conduct a test to determine the optimal conditions for your specific formulation.

Another important factor to consider is the intended application of the mold. For frequently used molds exposed to high temperatures, opt for silicone that offers thermal stability. Alternatively, if you need a mold for intricate designs or detailed patterns, platinum-cure silicone may provide the precision required without compromising on the durability of the final product.

Tips: Always check the manufacturer's specifications for the silicone rubber you select to ensure it meets the requirements of your project, including any necessary certifications for safety and compliance.

| Silicone Type | Curing Method | Applications | Key Properties |

|---|---|---|---|

| Tin-Cure Silicone | Room Temperature Vulcanization (RTV) | Molds for casting, special effects | Cost-effective, easy to use, moderate heat resistance |

| Platinum-Cure Silicone | Room Temperature Vulcanization (RTV) | Food-safe molds, dental applications | Durable, flexible, high tear strength |

| High-Temperature Silicone | Heat Cure | Industrial molds, automotive parts | Excellent heat resistance, high tensile strength |

| Liquid Silicone Rubber (LSR) | Two-Part Curing | Medical devices, precision molds | High accuracy, durability, fast curing |

| Silicone Gel | Room Temperature Vulcanization (RTV) | Soft molds, cushioning applications | Soft, flexible, good shock absorption |

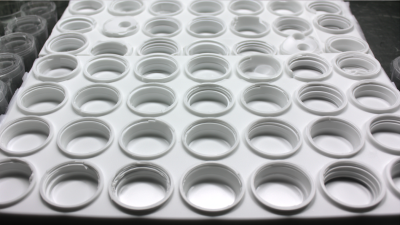

Caring for silicone molds is essential to ensure their longevity and optimal performance in mold making. Regular maintenance can significantly extend the life of your molds and keep them in great shape for future projects. One key tip is to clean your molds thoroughly after each use. Use mild soap and warm water to remove any residues; avoid harsh chemicals that could degrade the silicone. Additionally, ensure that the molds are completely dry before storing them to prevent any mold or mildew formation.

Another important aspect of maintaining your silicone molds is proper storage. Store them in a cool, dry place away from direct sunlight, which can cause the silicone to become brittle over time. It’s also wise to avoid folding or crumpling the molds; instead, try to keep them flat or upright to preserve their original shape. Regular inspection for any signs of wear and tear can help catch potential issues early, allowing you to address them before they affect your projects. By following these tips, you can enjoy the benefits of silicone molds for many years to come.

When it comes to mold making, choosing the right silicone rubber is crucial for maximizing the lifespan of your molds. One common pitfall is selecting a material that isn’t compatible with the intended casting substance. According to a report by the American Institute of Rubber Manufacturers, approximately 30% of mold failures are attributed to chemical incompatibility. Ensuring that the silicone rubber can withstand the specific resins or other materials you plan to use is essential for extending mold longevity.

Another significant mistake to avoid is improper curing. A study published in the Journal of Polymer Science highlights that molds cured at suboptimal temperatures can result in reduced elasticity and increased brittleness, diminishing their usability. For instance, curing below the recommended temperature can reduce tensile strength by up to 25%. Therefore, following the manufacturer's guidelines rigorously and investing in reliable temperature control equipment can greatly enhance your mold's performance and lifespan. Ensuring proper preparation and processing techniques can save time and resources in the long run, allowing for more successful casting results and efficient mold-making practices.