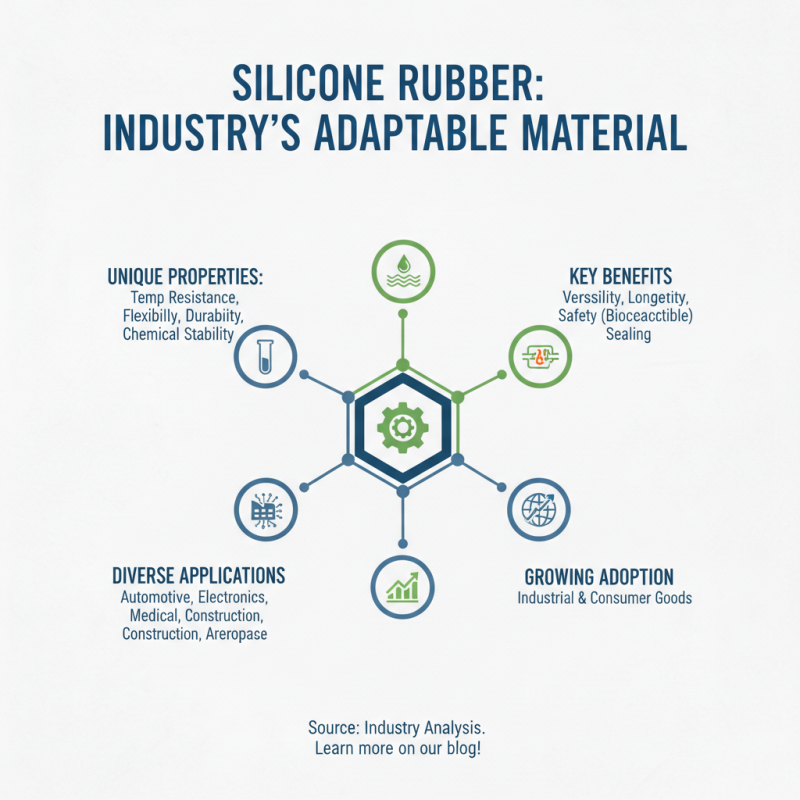

Silicone rubber has become a cornerstone material across various industries, appreciated for its unique properties and versatility. With a wide range of applications, silicone rubber is employed in everything from automotive components to medical devices, making it a vital part of modern manufacturing and product design. Its inherent characteristics, such as high-temperature resistance, flexibility, and durability, allow it to perform exceptionally well in challenging environments, thereby meeting the stringent demands of various sectors.

The benefits of silicone rubber are manifold, as it not only enhances the functionality of products but also helps improve their longevity and reliability. Moreover, silicone rubber is often favored for its biocompatibility, making it suitable for use in healthcare applications without compromising safety. As we explore the top ten uses of silicone rubber, it becomes evident how this remarkable material is revolutionizing industries and contributing to innovative solutions. From everyday household items to specialized industrial products, silicone rubber's applications are limitless, positioning it as a go-to choice for engineers and designers alike.

Silicone rubber is a versatile material that exhibits exceptional properties, making it suitable for a wide range of applications. Its key characteristic is its ability to withstand extreme temperature variations, from -60°C to over 250°C, which allows it to maintain its integrity and functionality in both hot and cold environments. This thermal stability, combined with excellent resistance to aging, UV light, and moisture, makes silicone rubber an ideal choice for outdoor applications and products exposed to harsh conditions.

Aside from its temperature resistance, silicone rubber also boasts remarkable flexibility and elasticity. This elasticity enables it to deform and return to its original shape, which is particularly beneficial in applications like seals, gaskets, and O-rings where a tight fit is crucial. Furthermore, silicone rubber is non-toxic and inert, ensuring safety in applications involving food contact or medical devices. Its biocompatibility is another notable property, making it suitable for a variety of healthcare applications, including implants and surgical instruments. With its unique combination of durability, versatility, and safety, silicone rubber continues to be an essential material across numerous industries.

The use of silicone rubber has become increasingly prevalent across various industries due to its unique properties and benefits. One of the standout features of silicone rubber is its remarkable temperature stability, withstanding conditions ranging from -60°C to 230°C, making it ideal for applications that require extreme thermal resistance. According to a report by Research and Markets, the global silicone rubber market is projected to reach USD 10.47 billion by 2025, driven by its expanding applications in automotive, aerospace, and healthcare sectors.

In the automotive industry, silicone rubber's flexibility and durability enable it to be used in components such as gaskets, seals, and insulators, which can enhance product longevity and performance. Furthermore, in the healthcare sector, silicone rubber is favored for medical devices and implants due to its biocompatibility, which minimizes the risk of adverse reactions. A study published in the Journal of Biomedical Materials Research highlighted that silicone elastomers are often used for prosthetics and surgical devices, demonstrating their essential role in improving patient outcomes. As industries continue to recognize these benefits, the versatility of silicone rubber is expected to drive further innovation and application development.

Silicone rubber is an incredibly versatile material that has found its way into countless household products due to its unique properties. One of the most significant benefits of silicone rubber is its resistance to extreme temperatures, enabling it to maintain functionality in both hot and cold environments. This resilience makes it ideal for kitchenware, such as baking mats and spatulas, which must withstand high temperatures without degrading. Additionally, silicone is non-stick and easy to clean, further enhancing its appeal for everyday use in items ranging from cooking utensils to food storage containers.

Another prominent application of silicone rubber in household items is in the realm of personal care products. Its flexibility and softness make it an excellent choice for items like toothbrushes, silicone facial scrubbers, and even baby products such as teething toys. These items benefit from silicone's hypoallergenic qualities, making them safe for sensitive skin and mouths. Furthermore, silicone’s durability means that these products can last much longer than those made from other materials, reducing waste and providing consumers with cost-effective solutions for their household needs.

Silicone rubber has emerged as a critical material in both the automotive and aerospace industries, largely due to its remarkable properties such as thermal stability, flexibility, and chemical resistance. According to a report by Research and Markets, the global silicone market in the automotive sector is projected to grow significantly, driven by the increasing demand for lightweight materials that can withstand harsh environments. This versatility allows silicone rubber to be utilized in various applications, ranging from seals and gaskets to insulation materials, enhancing the overall efficiency and safety of vehicles.

In aerospace applications, silicone rubber plays a vital role in ensuring reliability and performance under extreme conditions. The material's ability to operate effectively at temperatures ranging from -40°F to over 400°F makes it ideal for components that experience significant thermal fluctuations. A study published in the Journal of Aerospace Engineering highlights the increasing use of silicone in critical applications such as engine seals, cockpit instrumentation, and fuel system components. By minimizing the risk of failure and enhancing the longevity of aerospace systems, silicone rubber contributes to safer and more efficient flight operations, emphasizing its importance in the advancement of modern aviation technologies.

| Application | Benefits | Industry |

|---|---|---|

| Gaskets and Seals | Excellent sealing capabilities, resistance to extreme temperatures | Automotive, Aerospace |

| Hoses | Flexible, durable, and resistant to weathering | Automotive |

| Electrical Insulation | High dielectric strength, flame retardant | Aerospace, Automotive |

| Molded Parts | Versatile, can be produced in various shapes and sizes | Aerospace |

| Dampers and Vibration Isolation | Excellent damping properties, noise reduction | Automotive |

| Thermal Barriers | Excellent thermal stability and heat resistance | Aerospace |

| Sealants | Weather resistant, long-lasting adhesion | Automotive |

| Wiring Insulation | Resistance to abrasion and heat, flexible | Aerospace |

| Adhesive Components | Strong bonding capabilities, chemical resistance | Automotive, Aerospace |

| Vibration Dampening Pads | Reduction in noise and vibration transmission | Automotive |

Silicone rubber is rapidly becoming a cornerstone material in the medical and electronics sectors due to its unique properties and versatility. In the medical field, silicone rubber is prized for its biocompatibility, making it safe for use in various medical devices and implants. This material can withstand high temperatures and sterilization processes, ensuring that it maintains its integrity and performance even in hygienically critical applications. From catheters and surgical instruments to seals and gaskets, silicone rubber's elasticity and durability enhance the reliability and longevity of medical products, providing patients and healthcare providers with added peace of mind.

In the realm of electronics, silicone rubber is utilized for its excellent insulating properties and resistance to extreme temperatures. It serves critical roles in the manufacture of components such as connectors, seals, and encapsulation materials. The flexible nature of silicone enables it to protect sensitive electronic components from moisture, dust, and other environmental factors, which is essential for ensuring the longevity and functionality of devices. Furthermore, its ability to maintain performance in various temperature ranges makes silicone rubber a preferred choice for automotive and consumer electronics, where exposure to heat and cold is a common challenge. This innovative material continues to evolve, driving advancements in both medical technology and electronic device design.