The landscape of manufacturing is evolving rapidly, with innovative solutions emerging every day. Among these trends is plastic dip molding, a method that transforms the way products are designed and manufactured. This technique involves coating objects with a layer of liquid plastic, creating a durable and functional surface. The beauty of plastic dip molding lies in its versatility.

In 2026, we are likely to see more industries adopting this method to achieve customized designs. Its applications range from automotive parts to electronic devices. However, the process is not without challenges. Businesses often grapple with the consistency of coatings and the environmental impact of plastics. Addressing these issues will be crucial in shaping the future of plastic dip molding.

As we delve deeper into the trends, fascinating insights will emerge. This includes the integration of eco-friendly materials and advanced technologies. While plastic dip molding holds great promise, reflection on these emerging trends is essential. The need for balance between innovation and sustainability will define the industry's path forward.

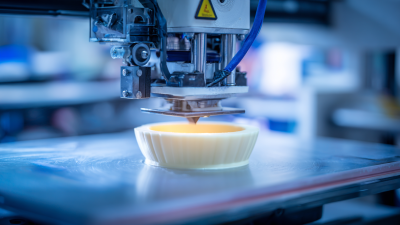

The landscape of plastic dip molding is evolving rapidly as we approach 2026. Innovative technologies are reshaping how manufacturers approach product designs. Specifically, advancements in automation are streamlining the molding process. This leads to faster production times and reduced labor costs. However, automation can introduce challenges in quality control. Rapid production could lead to inconsistencies if not carefully monitored.

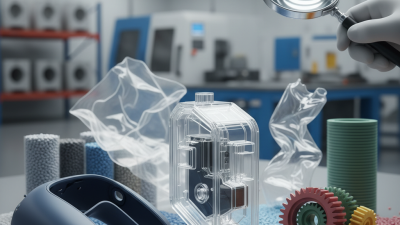

Another emerging trend is the integration of sustainable materials in dip molding. Manufacturers are exploring bio-based plastics and other eco-friendly options. This not only addresses environmental concerns but also attracts a larger consumer base. Yet, the durability of these materials remains a pressing question. Balancing sustainability with performance is a challenge.

In addition, digitalization is impacting the industry. The use of data analytics enhances decision-making processes. Manufacturers can optimize production efficiency and reduce waste using insights from real-time data. However, the reliance on technology raises concerns about cybersecurity threats. Companies must remain vigilant to protect their intellectual property. The future of plastic dip molding is bright but requires thoughtful navigation of these complexities.

Sustainable materials are reshaping the landscape of plastic dip molding. As industries push for greener solutions, manufacturers are exploring alternatives to traditional materials. These sustainable options can reduce carbon footprints. They are often derived from renewable sources. Using bio-based plastics can be a game-changer. They are not only eco-friendly but also lightweight and strong.

Consider incorporating recycled materials into your production process. This can reduce waste and lower costs. However, testing is essential. Sometimes, recycled materials may not meet performance standards. This can be a setback for manufacturers striving for quality.

It's crucial to stay informed about new materials. Research and development can lead to innovative solutions. Collaborate with suppliers who prioritize sustainability. Keeping an open mind can lead to unexpected outcomes. The journey toward sustainable manufacturing is continuous. Embrace the challenges and be ready to adapt.

Customization in plastic dip molding is gaining traction as industries seek tailored solutions. In 2026, we expect to see a notable rise in demand for bespoke applications across various sectors. A recent study indicated that the custom plastic molding market is projected to grow by 4% annually. This growth highlights the increasing need for adaptable manufacturing processes.

Industries such as automotive, healthcare, and consumer goods are leading this trend. Customization allows for improved functionality and aesthetics. Specific designs like ergonomic shapes for medical devices or intricate components for automotive parts are on the rise. Notably, 70% of manufacturers believe that customized components enhance product performance. However, the challenge lies in balancing manufacturing efficiency with the intricacies of tailored designs.

Tips: Invest in technology that supports rapid prototyping. This can help streamline the design process. Collaborate closely with clients to understand their needs. Regular communication can avoid misunderstandings and lead to better outcomes. Reflecting on the customization journey can unveil areas for improvement. Mistakes can be a learning opportunity, helping you to innovate further.

In the ever-evolving realm of plastic dip molding, efficiency improvements are crucial. Automation stands at the forefront of this transformation. By integrating robotic systems, manufacturers enhance precision in every step. These machines can work around the clock, tirelessly producing high-quality products with minimal human intervention. Interestingly, while automation reduces labor costs, it also raises questions about workforce dynamics.

Process optimization plays a pivotal role too. Streamlining workflows helps in reducing waste and saving time. For example, refining the heating processes can lead to consistent product quality. Yet, these changes can be bittersweet. Some workers may find the shift daunting, grappling with new technologies. It's essential to provide training and support during this transition.

Innovative solutions are great, but they come with their challenges. Balancing efficiency with human expertise requires reflection. How do we best utilize both? The goal should be a harmonious integration, merging technology and craftsmanship seamlessly. Exploring these dynamics will shape the future of plastic dip molding, ensuring it remains at the cutting edge of manufacturing.

The landscape of plastic dip molding is rapidly evolving. Market demands significantly influence techniques and technologies. A recent report indicates a 15% increase in demand for eco-friendly molding processes. Manufacturers are increasingly focusing on sustainable materials. This shift responds to consumer preferences for greener products.

While innovation is essential, challenges remain. Adapting to new regulations can be tough. Not all manufacturers have the resources to invest in new technologies. Also, the transition to sustainable methods sometimes leads to higher production costs. According to industry studies, 30% of companies still rely on outdated techniques.

Emerging trends showcase potential solutions. Companies are exploring automation, which could improve efficiency. Reports suggest automation might reduce labor costs by up to 25%. However, integrating advanced technology demands substantial upfront investment. The future of plastic dip molding hinges on balancing innovation with practicality. There’s a need for continuous reflection on these challenges as the industry moves forward.