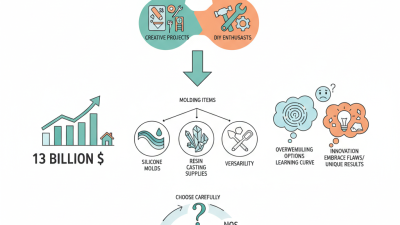

Mold making continues to evolve rapidly. The industry's growth is supported by a recent report from MarketsandMarkets, indicating a projected growth rate of 4.5% from 2021 to 2026. This growth highlights the increasing demand for precision molds in diverse sectors, including automotive and consumer goods.

As we approach 2026, advanced techniques in mold making are transforming production methods. 3D printing and CNC machining are leading the way, offering more efficient and cost-effective solutions. The incorporation of smart technologies is also on the rise. Yet, challenges persist, such as a skills gap among the workforce and high material costs. Addressing these issues is crucial for maintaining industry momentum.

Upgrading mold making capabilities is essential for competitive advantage. Companies are investing in training and technology to keep up with advancements. However, not all organizations are adapting effectively. This situation necessitates reflection on strategies and approaches to mold making. Embracing innovation while overcoming obstacles will define the future of this vital industry.

As we approach 2026, mold making techniques are witnessing significant transformations. Emerging technologies and advanced materials are reshaping the industry. According to a recent report by Industry Research, the mold making market is expected to grow by 5.4% annually. This growth reflects a shift towards innovative methods.

Digital design and 3D printing have become pivotal. By 2026, these techniques will dominate the market. They allow for rapid prototyping, minimizing production time and costs. However, their integration may challenge traditional mold makers. Adapting to this change is crucial for survival in a competitive landscape.

**Tip:** Invest in training for your team. Familiarize them with new software and techniques.

Sustainability is another emerging trend. Eco-friendly materials are being prioritized. Also, energy efficiency in production processes is gaining traction. Reports indicate that companies focusing on green practices are seeing increased customer interest. Nevertheless, balancing quality and sustainability remains a complex challenge.

**Tip:** Explore local suppliers for sustainable materials. This can reduce your carbon footprint and support the community.

Overall, the mold making industry is evolving. Staying informed on these trends is essential for future success.

This chart illustrates the emerging trends in mold making techniques for 2026, showcasing the projected adoption rates of various techniques. 3D printing leads the way, indicating a significant shift towards innovative and efficient methods in the industry.

When it comes to mold fabrication, the choice of materials is crucial. Advanced techniques in 2026 demand precision and resilience. Silicone rubber, for example, is a popular choice due to its flexibility and durability. It allows for intricate details to be captured, even in complex designs. However, not every project benefits from silicone. It’s essential to evaluate your specific needs.

Another interesting material is polyurethane. It can withstand high temperatures and is ideal for short production runs. Yet, some users report challenges in achieving perfect finishes. Experimentation is key here. You might find that while one material works well in general, it may not meet your expectations for every project. Understanding these nuances can save time and frustration.

[Insert Image]Thermoplastics also offer unique advantages. They can be reshaped with heat, allowing for easy adjustments. Yet, they require careful handling, as the wrong temperature can lead to warping. The learning curve with these materials is steep, but the potential rewards are worth the effort. Reviewing your processes and continuously adapting your approach will lead to better results in mold making.

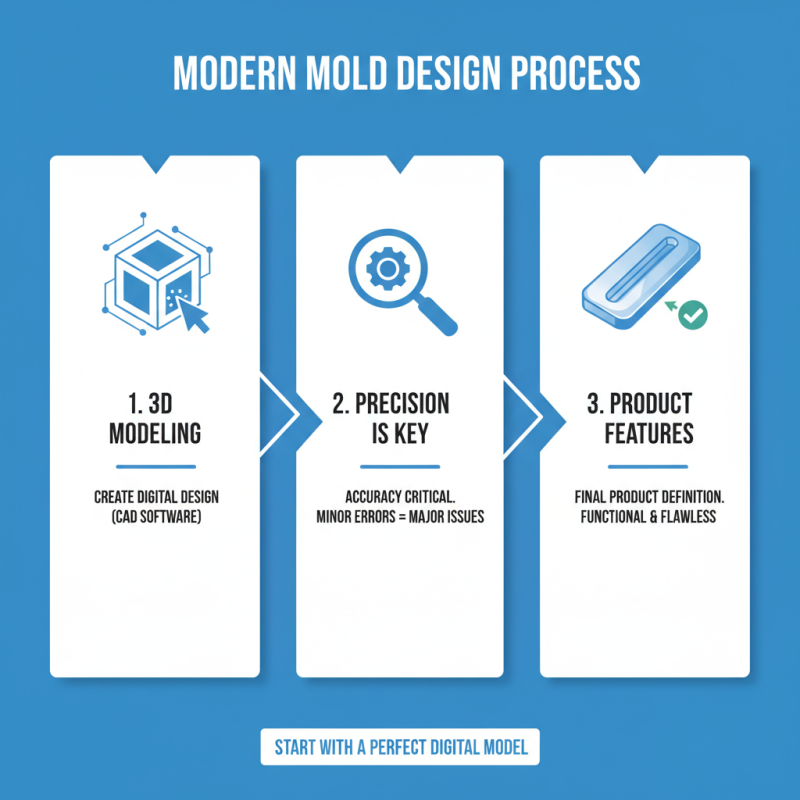

When diving into modern mold design processes, it's crucial to grasp the fundamentals. The design process typically starts with 3D modeling. Designers create a digital model using CAD software. This model highlights the desired product features. Precision is key. Even minor errors can lead to major issues later.

Once the model is finalized, prototypes are developed. These prototypes help visualize the final product. They are often made from materials less costly than the production mold. While prototyping offers significant insights, it is not without challenges. Adjustments can lead to delays. It’s vital to remain flexible during this phase.

Here are some tips to improve this process. Always communicate with your team. Open discussions can uncover problems early. Review your designs multiple times. This can prevent costly mistakes as you move forward. Also, test different materials during prototyping. This can reveal which works best for the final mold. Iteration is essential, but it takes time and patience. Plan accordingly to avoid rushed decisions.

The mold-making industry is undergoing rapid transformation. Innovative technologies are shaping its future. According to a recent market report, the global mold market is expected to reach $20 billion by 2026. This growth is driven by advancements in materials and production methods.

3D printing is becoming a game-changer. It allows for quicker prototyping and complex shapes that traditional methods can't achieve. Companies can now produce molds in days instead of weeks. This reduces lead times and costs, yet some firms struggle with quality consistency. Adopting this technology requires careful planning.

Another trend is the use of smart manufacturing. Automated systems and AI are optimizing production processes. Data analytics provide insights to enhance efficiency. However, many businesses find it challenging to integrate these systems. Training staff and adapting workflows take time. The transition can be bumpy, but the long-term benefits could be substantial. As the industry evolves, staying updated on these innovations is crucial.

| Technique | Description | Benefits | Challenges | Future Trends |

|---|---|---|---|---|

| 3D Printing | Additive manufacturing used for creating complex molds. | Speed, customization, reduced waste. | Material limitations, cost of equipment. | Increased use of bio-based materials. |

| Injection Molding | Using molten material injected into molds. | High volume production, precision. | High initial costs, longer setup time. | Integration with smart technologies. |

| CNC Machining | Computer-controlled cutting machines for mold fabrication. | Accuracy, material versatility. | Skill requirement, operational costs. | Automation and AI in machining. |

| Liquid Silicone Rubber Molding | Molding technique for flexible silicone parts. | Flexibility, excellent surface finish. | Limited to specific applications. | Growth in healthcare and consumer goods. |

| Hybrid Molding | Combination of various molding techniques. | Improved efficiency and flexibility. | Complex setup and processes. | Customization for niche markets. |

Sustainability in mold production is becoming increasingly vital. In 2026, companies must adopt eco-friendly practices. Better materials reduce waste. Biodegradable options are emerging, but they still need improvement. Engineers are experimenting with plant-based resins. These materials show promise but often lack durability.

Water usage is another concern. Efficient cooling systems can minimize waste. Yet, many factories still use outdated techniques. Reducing energy consumption is essential too. Solar power is a good idea, but initial costs can be high. Companies may hesitate due to budget constraints.

Additionally, recycling old molds can save resources. It's not universally practiced, but efforts are growing. Reusable molds are another avenue worth exploring. They can lower material costs and waste. However, creating a successful system for reusability requires effort. The industry must keep refining these practices for real progress. Environmental responsibility is a challenging journey, but it's necessary for the future.