In the rapidly evolving landscape of manufacturing, custom molding has emerged as a pivotal solution for companies seeking to innovate and meet the demands of a dynamic market. According to a report by Grand View Research, the global custom molding market is projected to reach $250 billion by 2025, underscoring the significance of tailored production techniques in various industries. This growth is largely driven by advancements in technology and the increasing need for precision-engineered products.

Expert in the field, Dr. Jane Smith, a leading researcher at the Institute of Advanced Manufacturing, notes, "Custom molding not only allows for versatility in design but also enhances the efficiency of production processes." Her insights highlight how custom molding solutions are not merely a trend but a necessary innovation for manufacturers striving to stay competitive. As we navigate through the top 10 custom molding solutions for 2025, it's essential to recognize the transformative potential these techniques hold for businesses looking to elevate their manufacturing capabilities and respond adeptly to customer needs in an ever-changing environment.

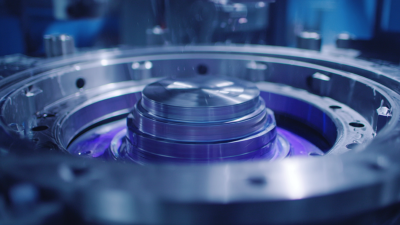

As we look ahead to 2025, innovative technologies are set to transform custom molding solutions, enhancing efficiency and product quality in manufacturing. Advances in 3D printing and smart automation are leading the charge, allowing for rapid prototyping and reduced lead times. According to a recent industry report by Smithers Pira, the global custom molding market is projected to reach $100 billion by 2025, driven by these groundbreaking technologies that improve design flexibility and material utilization.

Tip: To stay competitive, manufacturers should invest in these emerging technologies, as adopting 3D printing can significantly cut costs and production time for custom molds.

Furthermore, the integration of AI and machine learning in molding processes is streamlining production by predicting maintenance needs and optimizing workflows. This trend is expected to increase overall operational efficiency by up to 30%, according to Deloitte's manufacturing outlook. Such innovations not only minimize downtime but also enhance the quality and performance of molded products.

Tip: Regularly assess and update your technological capabilities to incorporate AI tools that analyze production data, facilitating informed decision-making and continuous improvement in molding operations.

When selecting the right custom molding partner, several key considerations come into play. Firstly, it is imperative to assess the partner’s technical expertise and manufacturing capabilities. Evaluate their experience in handling projects similar to yours, along with their understanding of the specific materials and processes required for your product. A partner with a proven track record in innovative molding solutions can significantly streamline the development process and enhance product quality.

In addition to technical expertise, consider the flexibility and scalability of the molding partner. Your manufacturing needs may evolve over time, so it is essential to choose a partner who can adapt to changing requirements, whether that means accommodating larger production runs or pivoting to new designs. Furthermore, communication and collaboration are critical factors; a partner that emphasizes transparency and is responsive to inquiries can foster a more productive working relationship. By focusing on these considerations, manufacturers can establish a successful partnership that drives innovation and efficiency in their custom molding projects.

The pursuit of sustainable practices in custom molding is not just a trend but a necessity for innovative manufacturing. As industries increasingly recognize their environmental impact, adopting eco-friendly techniques has become paramount. According to a recent report by the Association of Plastic Recyclers, only 9% of plastic products are recycled efficiently, highlighting the urgent need for sustainable alternatives in manufacturing processes. Implementing biodegradable materials and eco-conscious production methods can significantly reduce waste and carbon footprints.

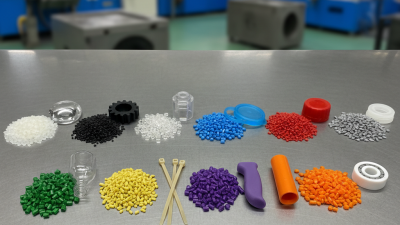

One effective approach is incorporating recycled materials into custom molding. For instance, the use of post-consumer recycled plastics can decrease overall material costs while reducing reliance on virgin resources. Additionally, energy-efficient machinery that lowers power consumption during the molding process not only cuts operational costs but also aligns with sustainability goals.

Tips for manufacturers include prioritizing partnerships with suppliers that emphasize sustainability in their materials and production methods. Furthermore, considering the lifecycle of products at the design stage can facilitate easier recyclability. By embracing these practices, companies can enhance their competitive edge while contributing positively to the environment.

As we approach 2025, the custom molding industry is witnessing remarkable shifts driven by innovative materials and technologies. Emerging trends indicate a growing focus on sustainable materials, particularly in the biodegradable space, where the market is projected to reach USD 22.8 billion by 2035, growing at a CAGR of 6.1%. Furthermore, the integration of advanced materials in custom molding applications is enhancing production efficiency while minimizing environmental impact.

Additionally, the rise of 3D printing technology is revolutionizing manufacturing processes, allowing for greater design flexibility and reduced costs. By 2030, the 3D printing industry is anticipated to exceed a valuation of $40 billion, indicating a substantial shift in production capabilities. The continuous evolution of materials and techniques in custom molding not only enhances product performance but also responds to the growing demand for eco-friendly solutions, ultimately transforming the landscape of innovative manufacturing.

In 2025, the landscape of custom molding solutions is set to revolutionize innovative manufacturing, evident in various successful implementations demonstrated across sectors. Case studies reveal that companies leveraging advanced molding techniques, such as injection molding and 3D printing, have significantly enhanced their production efficiency. For instance, a recent report indicated that the adoption of customized molding improved productivity by 30% in automotive parts manufacturing, showcasing the tangible benefits of tailored solutions.

One notable example is the establishment of specialized centers focusing on high-quality production processes, echoing the initiatives seen in regions like Fujian, where tea brands are intertwining agricultural heritage with modern manufacturing methods. By adopting such innovative molding strategies, these sectors can not only preserve their traditional craft but also meet the increasing demands of the global market.

**Tips:** When exploring custom molding solutions, consider the scalability and flexibility of the technology you choose. The latest industry reports suggest that companies prioritizing adaptability in their manufacturing processes witness a quicker return on investment. Additionally, fostering partnerships with training institutions can equip your workforce with the necessary skills to leverage these new technologies effectively.