In the competitive landscape of manufacturing, success in mold making is critical. With precise techniques, manufacturers can significantly enhance product quality. A recent industry report from the American Mold Builders Association highlighted that 80% of manufacturers see improved efficiency through advanced mold making methods. This underscores the importance of mastering these techniques.

Expert insights add depth to this understanding. John Smith, a renowned figure in the mold making industry, emphasizes, "Precision in mold making is not just beneficial; it's essential for meeting market demands." His perspective resonates with the ongoing evolution of manufacturing technologies.

However, achieving proficiency in mold making is not without challenges. Manufacturers often face issues like material imperfections and process inconsistencies. Addressing these requires constant reflection and a willingness to adapt. Keeping up with industry advancements can be daunting, yet the rewards for those who persevere are substantial.

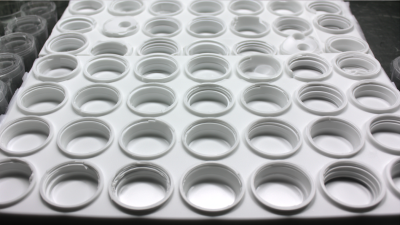

Effective mold making requires attention to detail. Start with precise designs. A well-thought-out mold design minimizes errors. Sketch ideas and visualize the final product early in the process. This helps identify potential issues. A flawed design leads to wasted time and materials.

Materials choice is crucial. Select durable materials for molds to withstand production demands. Cost-effective options may compromise quality. Test your materials adequately. A poor choice could ruin your project midway. Always be ready to adjust your techniques based on results.

Additionally, consistency is key. Ensure every mold meets the same standards. Even small variations can result in defective products. Document your processes and learn from mistakes. Reflect on past projects to improve future outcomes. Adaptability leads to better molds and success in manufacturing.

Material selection is crucial in mold making. The right materials can greatly influence the quality and durability of finished products. When choosing materials, consider their thermal properties, strength, and flexibility. For example, steel molds often last longer but can be costly. Conversely, aluminum molds are lighter and easier to work with.

Finding the right balance matters. Using a cheaper material might save money now but can lead to higher costs in the long run due to wear and tear. Mold failure can occur if the material can't withstand pressure. Pay attention to the specific requirements of your project.

Tip: Always run tests before fully committing to materials. Small changes can have significant impacts on production. Experimenting with different materials can yield surprising results. Don't overlook composites; they offer excellent strength-to-weight ratios. Another tip: consult with experienced colleagues. Their insights can help you avoid common pitfalls.

Designing efficient mold geometry is critical in manufacturing. Each decision affects the final product’s quality. The shape of the mold must align with the intended design. This includes considering draft angles and wall thickness. A slight error in angles can lead to difficult part removal. Uneven wall thickness can cause defects or warping during cooling.

Incorporating features like ribs and bosses can enhance mold strength. However, placing them incorrectly may complicate the molding process. Clean, clear lines in the design aid in material flow. It's essential to visualize how each element interacts. If the mold traps air or material, it can ruin the final product. Regular evaluation of these design aspects can prevent costly mistakes.

Moreover, testing different geometries before finalizing is invaluable. Prototyping allows designers to learn from failures. A mold design that seems perfect may not perform in practice. Reflection on past projects can inform better choices. This iterative process is key to mastering mold making techniques. Embrace the learning curve, and seek improvements continuously.

Incorporating advanced technologies in mold manufacturing processes is crucial for achieving efficiency and precision. Technologies like 3D printing enable rapid prototyping, allowing manufacturers to quickly iterate designs. This method reduces material waste. It also shortens lead times significantly. However, embracing such advancements can come with challenges. Training staff to use new tools takes time. Some may resist change due to existing workflows.

Automation in mold production offers another avenue for improvement. Robotics can increase speed while maintaining consistent quality. But integration isn’t always seamless. Machines require regular maintenance and calibration. Skills gap in handling such machinery is also a common hurdle. Balancing the need for innovation while ensuring effective operation is vital.

Data analytics plays a pivotal role as well. By analyzing production metrics, manufacturers can identify bottlenecks. This approach enhances decision-making, leading to more efficient processes. Yet, relying solely on data can lead to oversight of human elements in production. Finding that right balance remains a continual process of reflection and adaptation within the industry.

| Tip | Description | Technology Incorporation |

|---|---|---|

| 1. Utilize CAD Software | Employ advanced computer-aided design software to create precise mold designs. | 3D modeling and simulation. |

| 2. Invest in CNC Machining | Use CNC machines for accurate mold production and reduced manual errors. | High-speed cutting technologies. |

| 3. Implement 3D Printing | Adopt 3D printing for rapid prototyping to test mold designs quickly. | Additive manufacturing techniques. |

| 4. Use Simulation Software | Analyze flow, cooling, and ejection processes to optimize design. | Finite element analysis (FEA) tools. |

| 5. Opt for High-Quality Materials | Select premium materials that enhance durability and performance of molds. | Advanced polymer composites. |

| 6. Incorporate Automation | Automate repetitive tasks to increase efficiency and consistency. | Robotics and automated assembly. |

| 7. Enhance Cooling Systems | Optimize cooling processes to reduce cycle times and improve quality. | Conformal cooling designs. |

| 8. Regular Maintenance | Conduct regular maintenance checks to prolong the lifespan of molds. | Preventative maintenance software. |

| 9. Use Experienced Technicians | Hire skilled professionals with expertise in advanced mold making techniques. | Expert training programs. |

| 10. Monitor Production Processes | Implement monitoring systems to track production metrics and quality. | IoT and production analytics. |

Quality control in mold making is crucial for ensuring the production of high-quality products. Reports show that nearly 30% of defects in molded parts stem from poor mold design. Therefore, rigorous testing and monitoring processes are essential. Regular inspections help to identify issues early. This allows for prompt adjustments before production runs.

Tip: Utilize digital tools for real-time monitoring of mold performance. This can enhance precision and reliability during the manufacturing process.

Testing molds thoroughly before mass production is vital. Implementing advanced testing techniques can reveal flaws that would otherwise go unnoticed. For instance, stress tests can simulate real-world conditions, helping to validate mold durability. Statistics indicate that molds subjected to these tests have a 25% longer service life.

Tip: Create a comprehensive checklist for mold inspections. This should cover all aspects, from material integrity to functional performance. Engaging the team in this process promotes accountability and quality consciousness. Mistakes can happen. Reflecting on past projects can provide valuable insights for future improvements.

Mold making is a critical aspect of the manufacturing process that requires careful consideration and precision. To ensure successful mold fabrication, it's essential to select appropriate materials that can withstand the demands of production while providing the desired properties. Designing efficient mold geometry is also vital, as it influences the overall performance and cost-effectiveness of the mold.

Incorporating advanced technologies can greatly enhance mold manufacturing processes, leading to improved accuracy and reduced lead times. Furthermore, implementing best practices for quality control and testing can help maintain high standards and ensure the longevity of molds. By adopting cost-effective strategies for mold maintenance, manufacturers can extend the lifespan of their molds, ultimately bolstering productivity and profitability in mold making operations.