Rubberized dip coating is an innovative process that transforms ordinary surfaces. By applying a rubber-like finish, it enhances both protection and grip. This technique is popular in various industries, including automotive and consumer electronics.

During the application, objects are submerged in a liquid rubber solution. This step ensures a uniform coat, which protects against moisture and abrasion. The result is a durable and flexible layer that can withstand the test of time. Many users appreciate the tactile quality it brings to everyday items.

However, the process has its challenges. Achieving the perfect consistency can be tricky. Variations in temperature and humidity may affect the outcome. Users might need to experiment with different techniques. The beauty of rubberized dip coating lies in its versatility and potential for improvement. It invites creativity, yet requires careful attention to detail.

Rubberized dip coating is a protective process. It involves submerging an object into a liquid rubber solution. This method creates a thick, rubbery layer around the surface. It's useful for tools, electronics, and outdoor gear. The coating can enhance grip and protect against moisture and corrosion.

During the dip coating process, the object needs to be clean. Any dirt can disrupt the adhesion. After dipping, the item is usually hung to allow excess coating to drip off. Curing is essential; it sets the rubbery layer. Not all items may withstand the heat or solvents in the process, so testing on a sample could be wise.

Tip: Always wear gloves when handling rubberized coatings. The chemicals may irritate your skin.

Some imperfections can occur during the coating. Small bubbles might form, or the finish may not be uniform. It’s crucial to inspect the final product. Reworking the surface might be needed if the coating fails.

Tip: Keep the workspace well-ventilated. Fumes from the coating can be strong. Proper ventilation helps ensure safety during the process.

Rubberized dip coating is a popular process in various industries. It involves submerging an object in a liquid rubber compound. This method creates a flexible and durable coating that can resist moisture, chemicals, and abrasions. The key materials in this process play a vital role in the coating's performance and longevity.

The primary component of rubberized coatings is synthetic rubber. Natural rubber is also used but less frequently. Synthetic rubbers like SBR (styrene-butadiene rubber) and EPDM (ethylene propylene diene monomer) are prevalent. These materials provide excellent elasticity and resistance to degradation. Industry reports indicate that the global rubber coating market was valued at $1.45 billion in 2022. This market is expected to grow at a CAGR of 4.5% between 2023 and 2030, highlighting the importance of rubberized coatings in manufacturing.

Additives are significant too. Agents like curing accelerators and stabilizers are crucial for improving the chemical resistance and lifespan of the coating. Yet, choosing additives can be tricky; some may affect the coating's adhesion properties negatively. A balance is needed between functionality and durability. Misjudgments in this area could lead to premature failure, costing manufacturers time and resources. Understanding these material characteristics is essential for optimizing the rubberized dip coating process.

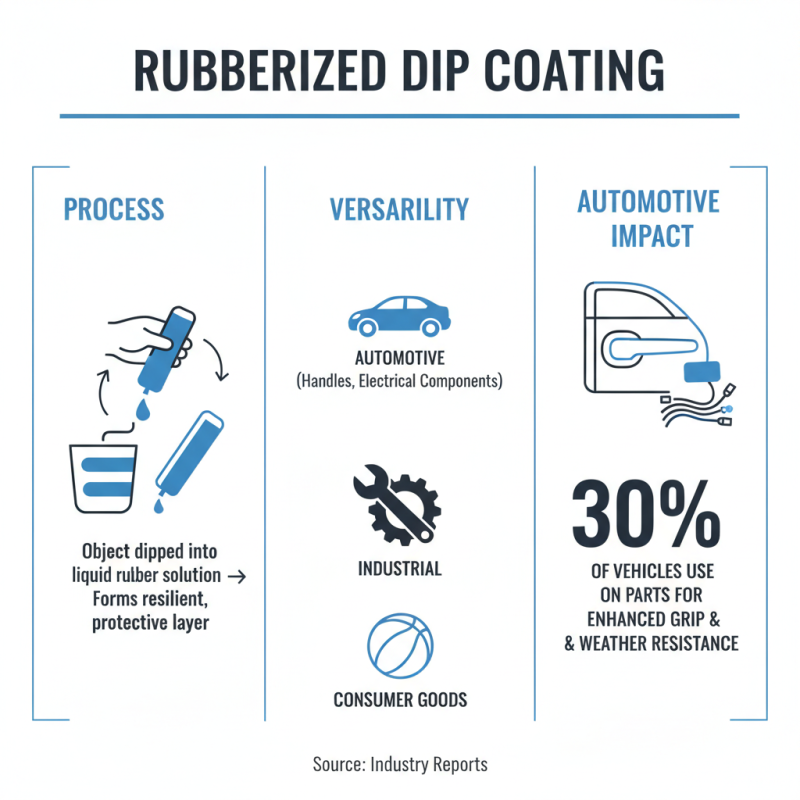

Rubberized dip coating is a versatile process used across various industries. This method involves dipping an object into a liquid rubber solution, which then cures to form a resilient, protective layer. The automotive industry is a key area where this technique shines. Reports indicate that over 30% of vehicles use rubberized coatings on parts like handles and electrical components, enhancing grip and weather resistance.

In the consumer electronics sector, rubberized dip coating provides a soft touch for devices. For example, smartphone cases often feature coatings that improve durability and comfort. According to market research, this segment is projected to grow by 15% annually, highlighting the increasing demand for protective and tactile surfaces. Yet, there’s an ongoing challenge. Achieving uniform thickness can be tricky, affecting performance and appearance. This inconsistency can be a source of concern for manufacturers looking for quality assurance.

The construction industry also utilizes rubberized coatings, particularly for tools and equipment. These coatings help in reducing slippage and providing grip on handles. However, some reports suggest that there is still a gap in understanding the long-term effects of these coatings under extreme conditions. Continuous improvement and research are essential for optimizing performance in diverse environments.

Rubberized dip coating is an innovative solution for various applications. It provides a protective layer to objects, enhancing their durability. This coating is applied by dipping items into a rubberized solution. Once dried, it forms a flexible, waterproof barrier. This barrier helps to prevent wear and tear, as well as corrosion.

The benefits of rubberized dip coating are significant. It offers excellent resistance against scratches and impacts. Tools and equipment treated with this coating last longer, making them a wise investment. Additionally, the grip provided by the rubberized surface can improve user handling. However, it's important to note that the application process requires attention to detail. Proper preparation is crucial for optimal results. A rushed job can lead to uneven coverage and a less effective shield.

Some may overlook the environmental impact of coatings. Choosing eco-friendly options can aid in reducing harmful effects. The balance between durability and sustainability is essential. Ultimately, rubberized dip coating is a practical solution, but mindful application and selection are key.

Rubberized dip coating offers unique advantages when compared to other coatings. This method involves immersing a substrate into a liquid rubber compound, allowing for an even coating. The end result is a thick, flexible layer that provides excellent protection. It excels in durability, offering superior resistance to impacts, abrasives, and various environmental factors.

In contrast, traditional coatings, like paint, may chip or fade over time. They often require careful application and multiple layers for adequate protection. Some coatings can peel, especially with exposure to moisture. Rubberized dip coating adheres tightly and resists wear and tear better than these alternatives.

While it has many strengths, rubberized dip coating is not without its faults. The drying time can vary significantly, affecting production schedules. In addition, achieving uniformity in thickness may be challenging for beginners. Assessing the effectiveness of this method compared to others requires careful thought and consideration. Each project has unique needs; understanding these is crucial before choosing a coating method.