Plastic trim plays a significant role in various applications. From automobiles to home décor, its versatility is notable. This material can enhance aesthetics and functionality simultaneously. For instance, in cars, plastic trim is used for both interior and exterior elements.

The approach to using plastic trim can differ greatly. In buildings, it often serves to hide imperfections or seams. It can also provide a cleaner look to walls and cabinets. However, not all plastic trim is created equal. Some alternatives may degrade over time, especially under harsh conditions.

While many appreciate its low cost and durability, concerns about long-term sustainability are rising. Plastic trim can contribute to waste if not disposed of correctly. Considering alternative materials or recycling options can be a worthwhile reflection.

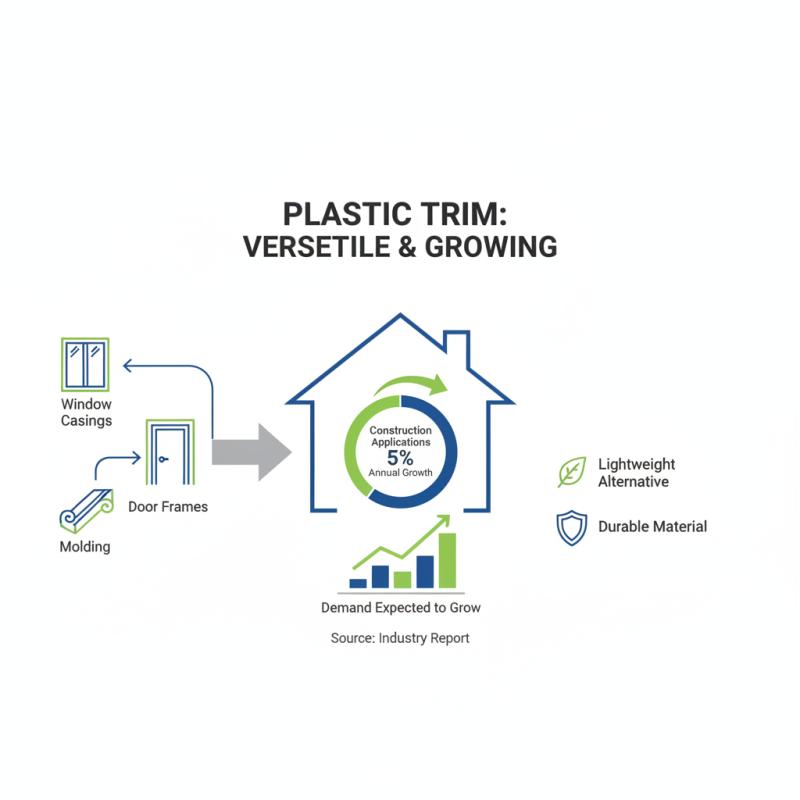

Plastic trim is a versatile material used in various industries. It typically consists of molded plastic that serves both functional and aesthetic purposes. In construction, plastic trim is frequently utilized for molding, door frames, and window casings. According to a recent industry report, the demand for plastic trim in building applications is expected to grow by approximately 5% annually. This growth underscores the popularity of plastic as a lightweight yet durable alternative to traditional materials.

Moreover, plastic trim is prevalent in the automotive sector. It is found in interior features, enhancing both design and comfort. Research indicates that plastic trim components can reduce vehicle weight, leading to improved fuel efficiency. This aspect is increasingly important as manufacturers strive to meet environmental standards. The durability of plastic also means lower maintenance costs over time.

Tips: When choosing plastic trim, consider its impact on your project’s overall sustainability. Not all plastics are created equal. Opt for recycled options when possible. Also, check the specifications to ensure they meet industry standards. Keep in mind that while plastic trim offers many advantages, it may not always be the ideal choice for high-heat environments. Evaluate the conditions it will face in use.

Plastic trim is versatile, commonly used in various applications. Different types of plastic trims offer distinct properties. This makes them suitable for specific tasks.

One popular material is PVC. It is lightweight, durable, and resistant to moisture. PVC is often used in construction and home improvement. Its flexibility makes it easy to install. Another common material is polypropylene. This type of plastic is known for its impact resistance. It is ideal for automotive parts and furniture trims. Polypropylene can withstand harsh conditions, which makes it valuable.

While these plastics have many benefits, they also present challenges. Over time, they can become brittle or discolor. Regular maintenance is necessary to extend their lifespan. Users must weigh their options carefully. The right choice depends on the intended application and environmental conditions.

| Type of Plastic Trim | Common Materials | Properties | Applications |

|---|---|---|---|

| PVC Trim | Polyvinyl Chloride | Durable, Weather-resistant, Lightweight | Outdoor Furnishings, Windows, Decking |

| ABS Trim | Acrylonitrile Butadiene Styrene | Strong, Rigid, Heat-resistant | Automotive Parts, Home Appliances, Furniture |

| Polyethylene Trim | Polyethylene | Flexible, Lightweight, Chemical-resistant | Packaging, Insulation, Playground Equipment |

| Polypropylene Trim | Polypropylene | Stiff, Fatigue-resistant, Impact-resistant | Containers, Automotive Interior, Textile Industry |

| TPU Trim | Thermoplastic Polyurethane | Elastic, Durable, Oil-resistant | Footwear, Sports Equipment, Mobile Cases |

Plastic trim plays a vital role in the automotive industry. It serves various functions, enhancing both aesthetics and functionality. For instance, plastic trim is often used on the exterior of vehicles. It provides a polished look while protecting sensitive components from damage. The lightweight nature of plastic means vehicles can improve fuel efficiency.

Inside the cabin, plastic trim helps to create an ergonomic design. This material is used in instrument panels, door handles, and center consoles. Manufacturers appreciate its versatility and ease of molding. With various textures and colors available, plastic trim allows for more design options. However, not all plastic trims are created equal. Some may not hold up well over time.

Recycling plastic trim can be challenging. Once it is damaged or worn out, it often ends up in landfills. The industry needs to explore better recycling methods. This could lead to more sustainable practices. Addressing such challenges will improve the overall impact of plastic trim in vehicles.

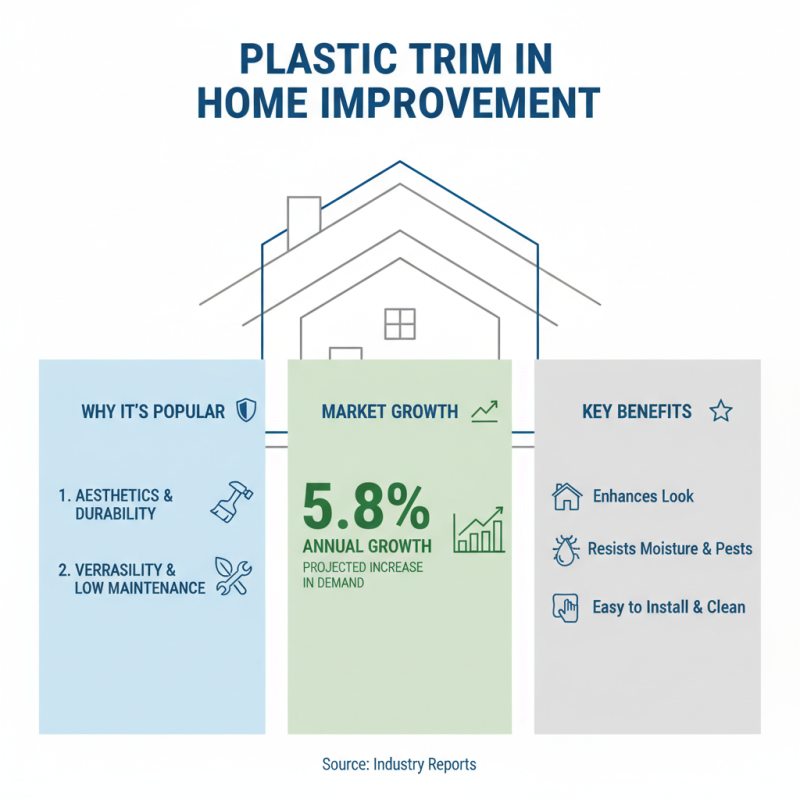

Plastic trim has become a popular choice in home improvement projects. It enhances both aesthetics and durability in various spaces. Reports indicate that the demand for plastic trim is rising, with a projected growth of 5.8% annually. This growth is largely due to its versatility and low maintenance.

In residential spaces, plastic trim serves multiple functions. It can frame doorways, baseboards, and window casings. The right trim can elevate a room’s design. Homeowners appreciate that it doesn’t warp like wood. In fact, a study showed that plastic trim can withstand moisture and harsh weather better than traditional materials. This durability is vital for areas like bathrooms and kitchens where humidity is high.

However, not all plastic trims are equal. Some manufacturers use lower-quality materials, leading to fading or cracking over time. Homeowners should examine product specifications closely. Choosing a low-grade option can backfire. It may also negatively impact resale value. Understanding these details is crucial for long-lasting beauty and functionality in home renovations.

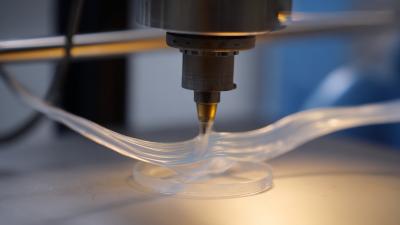

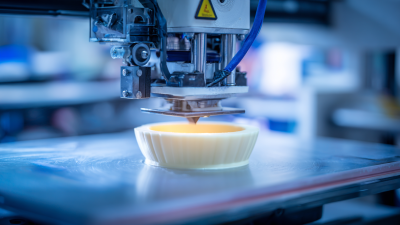

The future of plastic trim is being shaped by innovative developments and a focus on sustainability. New materials are emerging that offer better durability while reducing environmental impact. Biodegradable plastics are gaining popularity for interior and exterior applications. These materials can help lower the carbon footprint of vehicles, homes, and consumer products. However, the challenge remains: how to balance aesthetics and functionality with sustainable practices?

Recycling is another key aspect of future plastic trim development. Companies are exploring closed-loop systems to reclaim and reuse materials. These efforts could significantly reduce waste in the manufacturing process. Yet, there are complexities involved. Not all plastic trims are easy to recycle. Sorting and processing require advanced technologies. Some manufacturers still struggle to implement these systems effectively.

Consumer awareness is rising. People are more conscious of material choices and their environmental repercussions. This shift pressures manufacturers to adopt more sustainable practices. Despite this, resistance exists in some sectors. There’s a fear that sustainable options may compromise quality or increase costs. The ongoing dialogue is crucial. It brings attention to the need for innovations that meet market demands while staying eco-friendly.