Plastic dip coating is a revolutionary finishing technique that enhances both the aesthetic and functional properties of various materials. This versatile coating method allows users to create a durable, protective layer on a wide range of surfaces, from tools and automotive parts to household items and electronic devices. The unique characteristics of plastic dip coating make it an attractive option for both professionals and DIY enthusiasts looking to improve the longevity and visual appeal of their projects.

In this article, we will explore the diverse applications and benefits of plastic dip coating, highlighting its ability to provide a resilient barrier against elements such as moisture, corrosion, and abrasion. We will delve into the steps involved in the DIY process, offering valuable tips and tricks to ensure a flawless finish.

Whether you are looking to revamp old items or enhance the functionality of new ones, plastic dip coating can be a game-changer in your creative toolkit. Join us as we uncover the endless possibilities that this innovative technique can offer.

Plastic dip coating has gained significant popularity in both home and industrial applications due to its unique benefits. According to a report by the Freedonia Group, the demand for plastic dip coatings is projected to grow by 4% annually, reaching nearly $2 billion by 2025. This growth can be attributed to the coatings' exceptional durability and resistance to corrosion, chemicals, and abrasions. Additionally, plastic dip coatings offer a non-slip surface, making them ideal for various tools and equipment used in both residential and commercial settings.

When it comes to DIY projects, plastic dip coating is exceptionally user-friendly. It allows homeowners to revitalize and enhance the aesthetic appeal of metal items like tools, garden equipment, and furniture. For effective application, ensure that the surfaces are clean and dry before dipping. Applying several thin layers instead of one thick coat can lead to a smoother finish. It’s also beneficial to perform the project in a well-ventilated area to reduce off-gassing, which can be harmful in enclosed spaces.

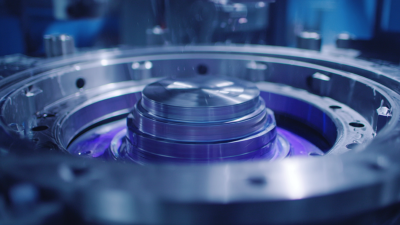

For industrial applications, plastic dip coatings provide a cost-effective solution for prolonging the lifespan of products. According to a study by MarketsandMarkets, the automotive and electronics sectors are significant consumers of these coatings due to their protective properties. Regular maintenance and periodic reapplication can ensure that coated items remain resistant to wear, vastly reducing the need for replacements and saving money in the long run.

This chart illustrates the various benefits of using Plastic Dip Coating in home and industrial applications. The data reflects the percentage of users who find each benefit appealing.

Plastic dip coating is a highly versatile finishing technique that has become increasingly popular for various applications in everyday life. One of the most common uses is in automotive customization. Car enthusiasts often use plastic dip to change the color or create unique designs on their vehicle’s exterior, providing a durable and removable option that protects the paint underneath.

Another significant application is in the DIY home improvement sector. Homeowners frequently use plastic dip to coat tools and hardware, providing a non-slip grip and protection against rust and wear. Additionally, it is commonly employed for garment embellishments, such as coating fabric accessories to achieve a stylish, waterproof finish. These applications not only enhance the aesthetic appeal but also extend the life of the items involved, making plastic dip a practical choice for various projects around the home.

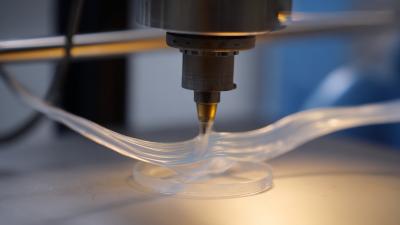

Plastic dip coating has gained popularity among DIY enthusiasts due to its versatility and ease of use. Whether you want to revamp old furniture, protect metal items from corrosion, or experiment with creative projects, plastic dip offers a durable and appealing finish. With the rise of digital tools such as laser cutters and 3D printing pens, the process has become even more accessible, empowering creators to achieve precise results and elevate their work.

For those embarking on DIY plastic dip projects at home, here are some essential tips to ensure success. First, prepare your surface thoroughly by cleaning and sanding it to enhance adhesion. Next, apply the plastic dip in thin, even coats to avoid drips and ensure an even finish. Additionally, consider using a spray booth or a well-ventilated area to manage overspray and associated fumes effectively.

Lastly, patience is key; allow adequate drying time between each coat to achieve optimal results. With these tips, you can unleash your creativity and transform everyday objects into stunning pieces that reflect your personal style.

Before applying plastic dip coating, surface preparation is crucial to achieving optimal adhesion and durability. A clean, smooth surface is essential; any contaminants such as grease, rust, or old paint can impede the bonding process. Recent studies indicate that surfaces treated with rust removers show a significant improvement in the adhesion of coatings, enhancing the overall longevity of the applied layer. For best results, it is often recommended to use products that effectively eliminate rust, ensuring a pristine base for the dip application.

In addition, mechanical cleaning methods, such as sanding or using a wire brush, can help achieve a more textured surface, which further promotes adhesion. Industry standards suggest that the proper surface roughness can increase the surface area for the plastic dip to cling to, thereby ensuring a more resilient finish. Following these best practices not only enhances the aesthetic appeal of your DIY projects but also extends the lifespan of the coating, allowing you to enjoy the benefits of plastic dip in various applications.

Plastic Dip coating has evolved far beyond its traditional applications, revealing innovative uses that resonate with contemporary trends in sustainability and aesthetics. This versatile coating, originally developed for automotive refinishing, is now being embraced in sectors such as DIY projects, home improvement, and even electronics. By providing a waterproof and protective barrier, Plastic Dip can be applied to various surfaces, allowing for customization with vibrant colors and textures. Its non-permanent nature makes it especially appealing for those who like to experiment with design without long-term commitment.

Moreover, recent advancements in materials science complement the growing interest in Plastic Dip coating. As industries pivot towards eco-friendly solutions, the incorporation of biodegradable materials and sustainable practices is becoming standard. The ongoing development of nanotechnology also opens new avenues for enhancing the properties of coatings like Plastic Dip, potentially improving their protective capabilities and environmental footprint. As DIY enthusiasts continue to seek out innovative, cost-effective solutions for projects, the applications of Plastic Dip serve as a testament to its adaptability in a rapidly evolving market.