In the ever-evolving landscape of product design, the role of molding experts has become increasingly pivotal in ensuring quality and innovation. According to a recent report by the Global Imaging Market Research, the demand for advanced molding techniques in industries such as automotive and consumer goods is projected to grow by 15% annually through 2025. This shift underscores the necessity for skilled molding experts who can harness cutting-edge technology and materials to transform conceptual designs into tangible products. By examining the intricacies of their craft, we can unveil the secrets behind achieving perfect product designs, ultimately leading to improved efficiency, reduced production costs, and higher customer satisfaction. As we delve deeper into the expertise of these professionals, we’ll explore the methodologies and insights that set them apart in a competitive market.

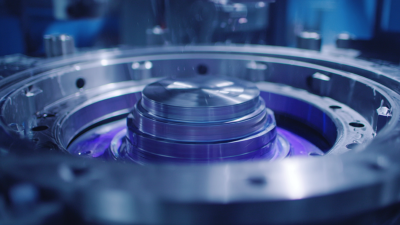

Understanding the fundamentals of molding techniques is crucial for achieving flawless product designs. Molding is a manufacturing process where raw materials are shaped into specific forms by using a mold. This technique is not only instrumental in defining the aesthetic aspect of a product but also influences its functionality and durability. By mastering various molding techniques—such as injection molding, blow molding, and compression molding—designers can create intricate products that meet precise specifications and consumer expectations.

Each molding technique has its unique advantages and challenges. For instance, injection molding is well-known for its ability to produce complex shapes with high precision and finish, making it ideal for mass production. On the other hand, blow molding is frequently employed in creating hollow products, such as bottles, presenting its own set of design considerations and material limitations.

Understanding these nuances allows designers to make informed choices when selecting the appropriate process, drastically impacting the overall success of the product design. By delving into the core principles of these techniques, experts can not only refine their designs but also foster innovation in product development.

The journey to becoming a successful molding expert is built on a foundation of key skills that distinguish the best from the rest. Firstly, a deep understanding of materials is essential. Molding experts must know the properties of various plastics, metals, and composites to choose the right material for each specific product design. This knowledge not only influences the quality of the final product but also impacts the cost and efficiency of the manufacturing process. Staying updated on advancements in material science can give these professionals an edge in innovation and sustainability.

The journey to becoming a successful molding expert is built on a foundation of key skills that distinguish the best from the rest. Firstly, a deep understanding of materials is essential. Molding experts must know the properties of various plastics, metals, and composites to choose the right material for each specific product design. This knowledge not only influences the quality of the final product but also impacts the cost and efficiency of the manufacturing process. Staying updated on advancements in material science can give these professionals an edge in innovation and sustainability.

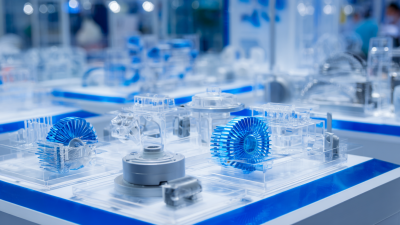

Another critical skill is proficiency in design software. Familiarity with Computer-Aided Design (CAD) tools enables molding experts to visualize and iterate designs before actual production. This technological expertise facilitates precise and efficient adjustments to prototypes, ensuring that the final product aligns with the original vision and meets industry standards. Furthermore, effective problem-solving abilities and strong communication skills enhance collaboration within multidisciplinary teams, ensuring that visions are shared and challenges are overcome collectively. Together, these skills equip molding experts to excel and deliver perfect product designs.

In the ever-evolving field of product design, leveraging essential tools and technologies is vital for achieving perfect results. According to a report by the Product Development and Management Association (PDMA), companies that integrate advanced design software and prototyping tools can reduce their product development cycles by up to 30%. This acceleration not only enhances efficiency but also allows for more iterative testing and refinement, leading to superior product outcomes.

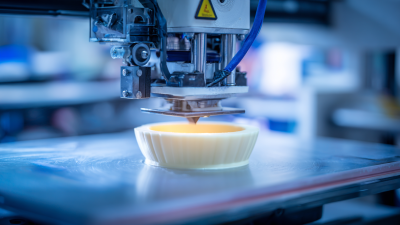

To streamline your design process, consider utilizing Computer-Aided Design (CAD) software. CAD tools facilitate precise modeling and allow designers to visualize products in 3D, according to a study by Gartner, which found that 72% of companies using CAD reported improved design accuracy. Additionally, incorporating 3D printing into your prototyping phase can drastically reduce the time and costs associated with traditional manufacturing processes, as highlighted by a recent survey from the Wohlers Report, which notes that 3D printing can cut prototyping time by as much as 50%.

Tip: Always stay updated with the latest software updates and industry trends to make informed decisions that enhance your design quality. Moreover, collaborating with cross-functional teams can provide diverse insights, ensuring that all aspects of a product's functionality are considered during the design phase. Emphasizing collaboration and technology will undoubtedly pave the way for more innovative and market-ready designs.

Collaborating with molding experts is crucial for achieving optimal product designs that meet both functionality and aesthetic requirements. According to a report published by the Society of Plastics Engineers, nearly 70% of product failures can be traced back to inadequate design collaboration, emphasizing the importance of integrating expert insights early in the design process. By engaging with molding professionals from the outset, design teams can identify potential manufacturability issues and refine their concepts to align with production capabilities.

Effective strategies for collaboration include fostering open communication channels and utilizing advanced simulation technologies. Tools like Moldflow and SolidWorks provide invaluable data, allowing teams to visualize how designs will perform during the molding process. In a case study highlighted by the American Injection Molding Institute, companies that adopted these technologies saw a 30% reduction in prototyping costs. By leveraging the expertise of molding professionals and incorporating cutting-edge tools, organizations can innovate more effectively and achieve superior product results.

When it comes to achieving perfect product designs, avoiding common pitfalls in molding processes is essential. One significant mistake is improper material selection. Choosing the wrong material for the intended product can lead to durability issues, aesthetic flaws, and functionality failures. To prevent this, always conduct thorough material research and testing to ensure compatibility with the design and end-use.

Another frequent challenge is the melting and cooling rates during production. If the temperature is not properly controlled, it can result in defects like warping or incomplete filling. It’s crucial to maintain consistent temperatures throughout the molding process.

**Tip:** Utilize temperature sensors and automated controls to monitor and adjust the heat settings in real-time for optimal results.

Additionally, neglecting to perform regular maintenance on molds can lead to deterioration and compromised product quality. A well-maintained mold will produce consistent and precise products.

**Tip:** Create a routine maintenance schedule that includes cleaning, inspections, and repairs to keep molds in prime condition and extend their lifespan.