In the rapidly evolving landscape of modern manufacturing, plastic parts have emerged as a cornerstone of efficiency and innovation. These components are not only lightweight and durable but also offer a level of design flexibility that is unmatched by traditional materials. According to Dr. Emily Carter, a leading expert in polymer engineering, “Plastic parts are revolutionizing the manufacturing process by providing solutions that were previously unimaginable.” This highlights the pivotal role plastic parts play in enabling engineers and designers to push the boundaries of product development.

As industries continue to embrace sustainability and cost-effectiveness, the significance of plastic parts becomes even more pronounced. They are integral to reducing the overall weight of products, which can lead to substantial energy savings and enhanced performance. In sectors ranging from automotive to electronics, the versatility of plastic components facilitates innovation, allowing manufacturers to create complex shapes and structures that meet rigorous performance standards. Through this exploration of the importance of plastic parts, we will delve deeper into their impact on modern manufacturing and the future of industrial design.

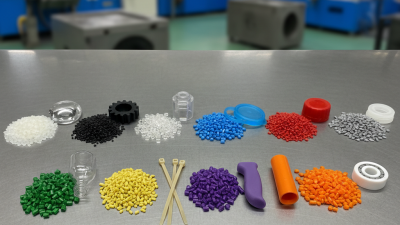

Plastic parts play a crucial role in modern manufacturing across various industries due to their versatility, cost-effectiveness, and enhanced performance. By allowing for complex designs and intricate shapes, plastic components enable manufacturers to create lightweight products that maintain durability. This is particularly important in sectors like automotive and aerospace, where weight reduction directly contributes to improved fuel efficiency and performance. Additionally, plastics can be molded into various forms, making them ideal for mass production, reducing manufacturing time while maintaining high quality.

Moreover, the use of plastic parts contributes significantly to innovation in product development. With advancements in polymer technology, manufacturers can now utilize specialized plastics that offer resistance to heat, chemicals, and environmental factors. This allows for the creation of more reliable and long-lasting products, which is vital in sectors like medical devices, electronics, and consumer goods. The adaptability of plastic allows for the integration of new features and functionalities, driving the development of smarter and more efficient products that meet the evolving needs of consumers and industries alike.

The use of plastic parts in modern manufacturing presents substantial advantages over traditional materials such as metals and ceramics. One of the primary benefits is the weight advantage; plastics are generally much lighter than their metal counterparts, contributing to reduced transportation costs and enhanced energy efficiency in applications like automotive and aerospace industries. This lightweight nature also allows for easier handling and assembly processes, streamlining production and minimizing labor costs.

Additionally, plastic parts are known for their versatility and adaptability. They can be molded into intricate designs that might be challenging or costly to achieve with metals or other materials. This capability not only enables manufacturers to customize products more effectively but also allows for more complex functionalities within a single component. Furthermore, plastics can often be resistant to corrosion, chemicals, and moisture, making them more durable in various environments. This durability leads to longer lifespans for products and reduced maintenance costs, which are significant factors in overall operational efficiencies for manufacturers.

| Dimension | Plastic Parts | Traditional Materials |

|---|---|---|

| Weight | Lightweight | Heavy |

| Cost Efficiency | Lower production costs | Higher production costs |

| Durability | Resistant to corrosion and chemicals | Prone to rust and degradation |

| Manufacturing Flexibility | Easily molded into complex shapes | Limited shaping capabilities |

| Thermal Properties | Good insulator | Conductive |

| Sustainability | Recyclable options available | Limited recyclable options |

| Aesthetic Variety | Wide range of colors and finishes | Limited color selection |

In modern manufacturing, plastic parts play a crucial role across various industries due to their versatility and cost-effectiveness. According to a report published by Research and Markets, the global plastic market is expected to reach approximately $650 billion by 2025, reflecting a compound annual growth rate (CAGR) of around 4.5% from 2020. This growth is largely driven by the increasing adoption of plastic components in automotive, electronics, medical devices, and consumer goods. For instance, in the automotive sector, plastic parts have replaced traditional materials to cut down on weight and enhance fuel efficiency, with estimates indicating that using lightweight plastics can result in a vehicle weight reduction of up to 50%.

Moreover, the application of plastic parts in the medical industry has surged in recent years, particularly with the demand for single-use medical devices driven by hygiene and safety standards. The market for plastic medical devices is projected to grow to over $40 billion by 2026, according to a report by Grand View Research. This is largely due to the advantages plastics offer, such as ease of sterilization, flexibility in design, and cost efficiency, which are vital for maintaining strict regulatory compliance while delivering safe and effective healthcare solutions. These examples underscore how integral plastic parts are in driving innovation and meeting the diverse needs of modern manufacturing across multiple sectors.

Sustainability has become a vital consideration in plastic manufacturing, as industries strive to balance innovation with environmental responsibility. The proliferation of plastic parts across various sectors has raised concerns regarding waste management and pollution. In response, manufacturers are increasingly adopting sustainable practices such as recycling, utilizing bio-based materials, and implementing circular economy principles. By rethinking the design and production processes, companies can minimize the negative impacts of plastic waste on the environment.

Moreover, advancements in technology enable the development of eco-friendly plastics that offer similar performance characteristics to traditional petroleum-based materials. These sustainable alternatives can reduce dependency on non-renewable resources and decrease carbon footprints. Additionally, the incorporation of life cycle assessment (LCA) in the manufacturing process helps companies evaluate the environmental impact of plastic products from creation to disposal. By prioritizing sustainability in plastic part production, manufacturers not only comply with regulatory standards but also cater to the growing consumer demand for environmentally friendly products, thus fostering a more sustainable future.

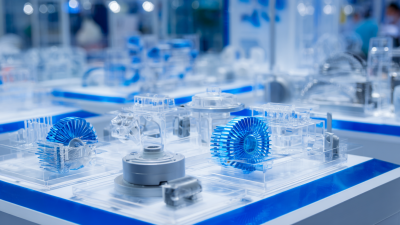

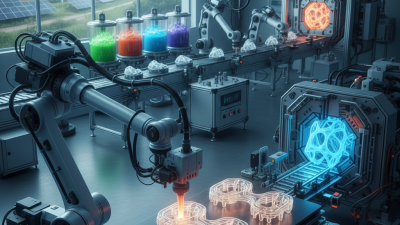

The future of plastic parts in manufacturing is poised for significant innovations, driven by advancements in technology and the growing emphasis on sustainability. One notable trend is the integration of smart manufacturing technologies, such as the Internet of Things (IoT) and artificial intelligence (AI). These technologies facilitate real-time monitoring and optimization of production processes, enhancing efficiency and reducing waste. As manufacturers adopt these smart solutions, plastic parts will become increasingly sophisticated, offering improved functionality and performance while maintaining cost-effectiveness.

Moreover, the focus on sustainable practices is reshaping the landscape of plastic manufacturing. The development of bio-based and biodegradable plastics is gaining traction, as industries seek eco-friendly alternatives to traditional materials. Innovations in recycling processes and the circular economy approach are also driving change, enabling manufacturers to reclaim and reuse plastic waste, thus minimizing environmental impact. These trends not only address regulatory requirements but also cater to the growing consumer demand for sustainable products, ensuring that plastic parts continue to play a crucial role in modern manufacturing while aligning with future environmental goals.