Casting plastic plays a crucial role in modern manufacturing and production. It enables the creation of intricate shapes and designs that are essential in various industries. A report by the Plastic Industry Association highlights that the North American plastic manufacturing market is valued at over $250 billion, showcasing its economic significance.

Experts like John Smith, a leading figure in the casting plastic industry, emphasize its importance: “Casting plastic allows for unparalleled versatility in product design and functionality.” This process not only enhances aesthetic appeal but also improves the durability of products. However, the reliance on casting plastic comes with environmental concerns, particularly regarding waste and recycling.

As industries evolve, the demand for sustainable practices rises. Companies must confront the challenges posed by the casting plastic process. It is vital to balance innovation with environmental responsibility. Adopting new materials or refining existing casting techniques can reduce ecological footprints.

Plastic casting plays a crucial role in modern manufacturing. It allows for the creation of intricate shapes and designs. This method can lead to reduced waste. Precision is vital in casting. A single error can affect the entire production batch.

Many industries benefit from plastic casting. Automotive parts, consumer goods, and electronics all rely on it. The flexibility of plastic can accommodate various styles and functionalities. However, not all casting processes yield perfect results. Imperfections can arise, leading to costly repairs. Manufacturers must always evaluate their techniques.

Sustainability is another concern. While plastic is versatile, its environmental impact can't be overlooked. Efforts are needed to reduce waste. Recycling and reusing plastics in production could enhance sustainability practices. The challenge lies in finding the right balance between efficiency and eco-friendliness.

Plastic casting has revolutionized manufacturing by offering unique advantages over traditional techniques. One significant benefit is the reduction in waste material. According to a report by the American Society of Plastic Engineers, casting can generate up to 30% less waste compared to machining. This efficiency not only minimizes environmental impact but also lowers production costs.

Additionally, plastic casting allows for intricate designs that are often impossible with methods like injection molding. Reports indicate that manufacturers can achieve complex geometries more easily, which leads to innovative product designs. This capability is essential in industries like aerospace where precision is critical.

Despite its advantages, challenges exist. Not all plastics are suitable for casting, and the process can be slower than traditional methods. This can be a barrier for businesses needing quick turnarounds. The learning curve for new applications can be steep, requiring investment in training and technology. Ultimately, while plastic casting presents compelling benefits, understanding its limitations is crucial for optimizing its use in production.

Plastic casting plays a vital role across various industries. In automotive manufacturing, it enables the production of lightweight yet durable components. These parts help improve fuel efficiency. Furthermore, intricate designs can be easily achieved, allowing for creative and efficient vehicle designs.

In the medical field, plastic casting is essential for creating custom devices. Prosthetics and surgical tools are often produced using this method. They offer personalized solutions to enhance patient care. However, the challenge remains in ensuring consistency and reliability in each piece. This requires careful monitoring during production.

Packaging is another area where plastic casting is critical. It helps create custom containers and protective packaging. This ensures products remain safe during transit. Yet, the environmental impact of plastic waste must be considered. Manufacturers are increasingly reflecting on sustainable practices to counterbalance these issues. Balancing innovation and environmental concerns is key moving forward.

| Application Area | Importance of Plastic Casting | Common Materials Used | Advantages |

|---|---|---|---|

| Automotive Components | Lightweight and durable parts for fuel efficiency | Polycarbonate, ABS, Nylon | Cost-effective production and design flexibility |

| Consumer Electronics | Complex shapes and designs for housing | Polypropylene, Acrylic, Polycarbonate | High precision and aesthetic finishes |

| Medical Devices | Reliable, sterile components for safety | Polyethylene, PVC, Polycarbonate | Bio-compatibility and regulatory compliance |

| Industrial Applications | Resistance to chemicals and wear | Polyethylene, Polyamide | Durability and longevity in harsh environments |

| Packaging | Sustainable and lightweight solutions | PET, Polystyrene, Bioplastics | Cost efficiency and recyclability |

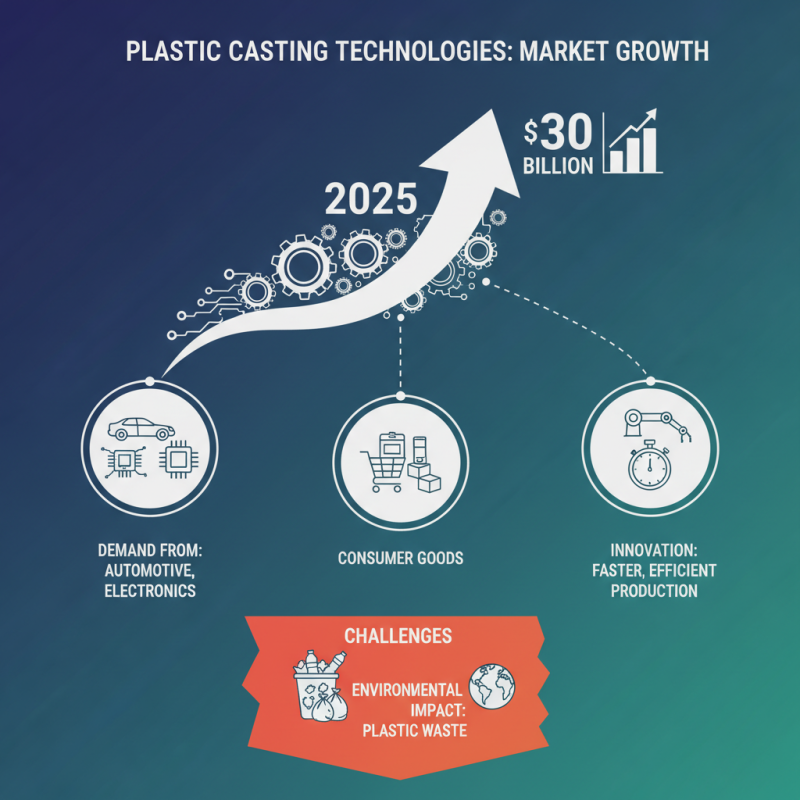

The growth in plastic casting technologies reflects significant market trends. The global plastic casting market is expected to reach $30 billion by 2025. This growth is fueled by increasing demand in automotive, electronics, and consumer goods sectors. Innovations in casting methods are making production faster and more efficient. However, challenges remain, such as the environmental impact of plastic waste.

Innovative techniques like 3D printing and bio-based materials are emerging. They aim to reduce waste and improve sustainability. According to recent studies, companies adopting these technologies report a 30% decrease in production costs. Yet, many still hesitate to fully embrace these innovations. Concerns about material performance and manufacturing processes persist.

Industry experts suggest that collaboration across sectors can drive change. Knowledge sharing is crucial for overcoming obstacles. Many companies are still unaware of the potential benefits. Transparency in processes could foster a greater acceptance of new methods. As the market evolves, the focus on sustainability will increasingly shape the development of plastic casting technologies.

Plastic casting plays a crucial role in manufacturing today. Its impact on sustainability is an important topic. Many manufacturers rely on plastic for its versatility and cost-effectiveness. However, the environmental implications cannot be overlooked.

The production process of plastic involves significant energy use. This contributes to greenhouse gas emissions. Additionally, plastic waste remains a serious concern. Casting plastics can lead to pollution if not managed properly. Often, these materials end up in landfills or oceans, posing risks to wildlife. The benefits of plastic should not overshadow these environmental challenges.

Some companies are exploring eco-friendly alternatives. These include bioplastics and recycling methods. Yet, progress can be slow. Many industries still use traditional plastics without consideration of their lifecycle. This raises questions about future practices in manufacturing. Balancing efficiency and sustainability is critical for a better future.