In the world of manufacturing, "casting plastic" has become an essential technique. Experts emphasize the importance of mastering this skill. John Smith, a noted specialist in the field, once said, "Understanding the nuances of casting plastic can transform your projects." His insight highlights the varied applications and potential of casting plastics.

This material is not just about molds and shapes. It requires precision and creativity. Working with casting plastic can be challenging. Many face issues like uneven surfaces or air bubbles. These imperfections remind us that patience is vital. Each project can serve as a learning experience.

Additionally, the choice of materials and techniques impacts the final product. The balance between quality and cost often leads to tough decisions. Mistakes can be costly. Yet, they offer valuable lessons. Adapting to challenges in casting plastic makes the process rewarding. Each step taken is crucial.

Casting plastic is a versatile material with a wide range of applications. It’s often used in sculpture, industrial parts, and prototypes. The unique properties of casting plastic offer great flexibility in design. For artists, casting can create intricate details and smooth finishes. In products, casting can improve durability and reduce waste.

When working with casting plastic, understanding its behavior is crucial. The material can shrink as it cures, affecting the final size. Mixing ratios need careful attention; too much hardener can lead to brittleness. Users often face challenges with bubbles forming in the mixture. These imperfections can be frustrating but are common in the process. Learning from each project will enhance future results.

Experimentation is key. Each casting process might yield different outcomes. Documenting successes and failures helps refine techniques. While mistakes can seem daunting, they are opportunities for growth. The journey of mastering casting plastic requires patience and resilience. Embracing imperfections can lead to unexpected creativity in your projects.

| Tip Number | Tip Description | Applications |

|---|---|---|

| 1 | Choose the right type of casting plastic for your project. | Automotive parts manufacturing |

| 2 | Prepare your molds properly to avoid defects. | Consumer electronics |

| 3 | Control the temperature during the curing process. | Furniture components |

| 4 | Take safety precautions, including using masks and gloves. | Medical device production |

| 5 | Mix components thoroughly to ensure quality. | Art and decorative items |

| 6 | Use release agents for easy mold removal. | Prototype models |

| 7 | Test your casting materials before large-scale production. | Custom parts for machinery |

| 8 | Store materials properly to prevent degradation. | Sports equipment |

| 9 | Follow manufacturer guidelines for best results. | Packaging solutions |

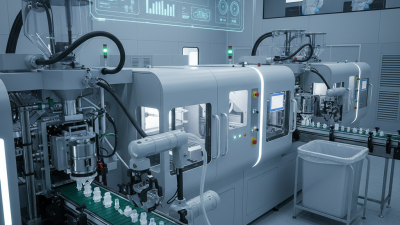

| 10 | Regularly clean and maintain your equipment. | Construction and building materials |

Preparing your workspace for casting plastic projects is crucial for success. A clean, organized area ensures better focus and minimizes errors. Dust and clutter can mess with your results. Dedicate a specific table or bench just for casting. This helps keep materials handy and reduces distractions.

Lighting is key in your workspace. Good lighting helps you see imperfections when mixing and pouring. Natural light works best, but bright artificial lights can also do the job. Ensure your workspace is well-ventilated, too. Fumes can build up, so open windows or use fans to maintain air circulation.

Don't forget to gather all necessary tools and materials ahead of time. Having everything within reach speeds up the process. Consider your mixing containers and tools. They should be clean and free from any residue. Mistakes can happen if you use dirty equipment. Finally, keep some cleaning supplies at hand. Accidental spills can occur, and it helps to be prepared.

Choosing the right type of casting plastic is crucial for any project. Different plastics serve varying needs in terms of durability, flexibility, and finish. Begin by assessing the project requirements. Will the end product need to withstand weight or stress? This choice affects your material selection significantly.

Tip: Consider using polyurethane resin for items requiring resilience. It's versatile and can handle a range of applications. For more decorative pieces, acrylic casting resin may be ideal. It offers a glossy finish but lacks durability compared to others. Be mindful of what each type can deliver.

Don’t forget to test the materials. You might find that what looks good on paper doesn’t perform well in practice. Errors can lead to wasted time and resources. Always keep an open mind about your choices. Document your findings to learn and improve for future projects. It’s all part of the creative process.

Casting plastic can be an intricate process. To achieve success, having the right tools and materials is essential. According to market research, over 70% of successful plastic casting projects rely heavily on quality materials. At the core are the resins. Epoxy and polyurethane are popular choices for different applications. Each offers unique properties that directly affect the final product's durability and finish.

In addition to resins, you’ll need various molds. Silicone molds are widely used due to their flexibility and ease of demolding. Using a mold release agent can also prevent sticking, yet many beginners overlook it. Data shows that improper mold use accounts for nearly 40% of casting failures. Other essential tools include mixing cups, stir sticks, and safety gear. Personal protective equipment is not just recommended; it is necessary to ensure safety during the casting process.

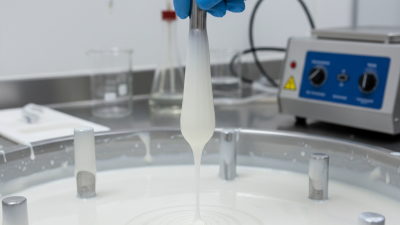

Pay attention to the curing environment. Temperature and humidity can drastically alter the properties of the final cast. An ideal range is typically around 70°F to 80°F (21°C to 27°C). Materials like fillers and pigments can also enhance your casting, but they require careful measurement. Mistakes in ratios can lead to poor adhesion or surface imperfections. Aim for precision but accept that learning often involves small errors.

When mixing and pouring casting plastic, achieving the right consistency is crucial. Start by measuring out the components carefully. Use a scale for accuracy. The mixing container should be clean and dry to prevent contamination. If the materials are not mixed properly, you may end up with uneven curing or unwanted bubbles.

Observe the mixing process closely. A common mistake is to rush through it. Take your time and mix thoroughly. The goal is to create a uniform texture. Pouring too quickly can also lead to air pockets, which compromise the finish. Be mindful of your pouring technique.

Temperature plays a role too. If it’s too cold, the plastic may not set correctly. A warm environment can improve the curing process. However, excess heat might cause the mixture to kick too fast. Monitor the temperature for the best outcomes. Always experiment with small batches first. It helps you learn from mistakes without wasting materials.