In the ever-evolving landscape of manufacturing, choosing quality rubber molded products has become a critical aspect for businesses aiming to maintain a competitive edge. According to John Smith, a renowned expert in the rubber molding industry, “The longevity and performance of rubber molded products directly influence the overall effectiveness of the operations they serve.” This insight highlights the significance of selecting the right materials and manufacturers to ensure optimal results.

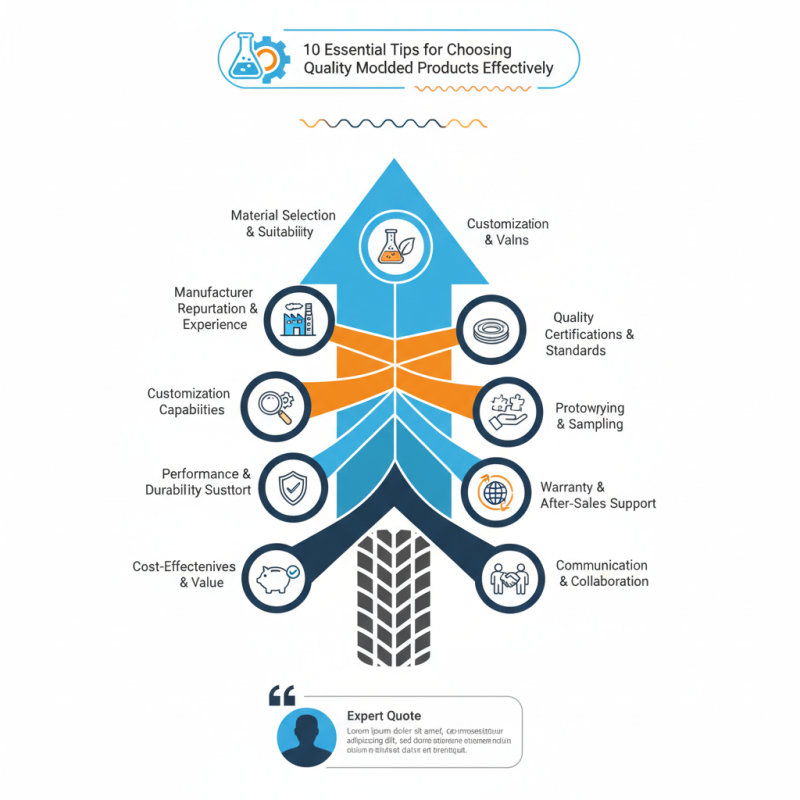

Understanding how to navigate the complexities of the rubber molded products market can be daunting for many organizations. The myriad of options available, coupled with varying quality standards, necessitates a well-informed approach to decision-making. By focusing on essential criteria and relying on expert recommendations, businesses can make significant strides in enhancing their product offerings and ensuring customer satisfaction. As we explore the ten essential tips for choosing quality rubber molded products effectively, we aim to empower companies with the knowledge they need to succeed in this crucial sector.

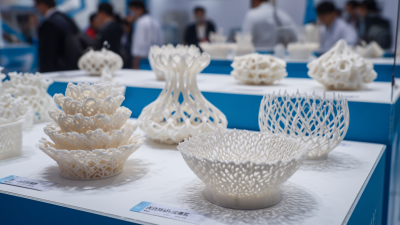

When selecting quality rubber molded products, understanding their key characteristics is crucial. Rubber molded products are widely used across various industries due to their flexibility, durability, and resistance to harsh environmental conditions. According to a report by Grand View Research, the global rubber market size was valued at approximately $51 billion in 2020 and is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. Key characteristics to consider include the type of rubber used, the molding process, and the specific application of the product.

The type of rubber—natural or synthetic—plays a significant role in determining the characteristics of the final product. For instance, natural rubber is renowned for its excellent tensile strength and elasticity, but it may not be suitable for high-temperature applications. On the other hand, synthetic rubbers, such as neoprene and silicone, offer improved resistance to oils, UV light, and extreme temperatures. It's also essential to examine the molding process, as methods like compression, injection, or transfer molding can influence the product's performance and cost-effectiveness. According to industry insights, products made through injection molding often exhibit higher precision and faster production times, making them preferable for high-volume applications where accuracy is critical.

Ultimately, understanding these key characteristics allows businesses to choose rubber molded products that best meet their operational needs, enhancing both efficiency and product lifespan.

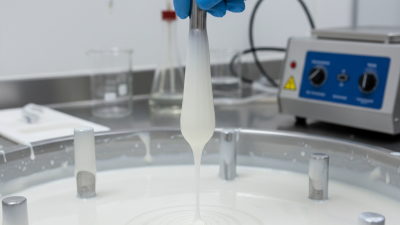

When selecting rubber molded products, the quality of materials is paramount. High-quality rubber typically exhibits superior elasticity, durability, and resistance to environmental conditions. According to a report by the International Rubber Study Group, synthetic rubbers now account for approximately 60% of the global rubber consumption, driven by advancements in material science that have significantly improved the properties of rubber products. When evaluating rubber materials, key indicators include hardness, tensile strength, and elongation at break, which should align with the specific requirements of the intended application.

In addition to mechanical properties, the environmental stability of rubber is crucial. Products should be evaluated for their resistance to UV light, ozone, and extreme temperatures, which can degrade lesser-quality materials. A comprehensive study by Grand View Research indicates that the demand for rubber molded products is projected to grow at a rate of 5.7% per year from 2021 to 2028, emphasizing the importance of selecting robust materials that can withstand such conditions over the product's lifespan. Potential buyers should also consider the manufacturing process, as vulcanization and the incorporation of additives can greatly influence the material's performance and longevity. By focusing on these essential attributes, one can effectively choose quality rubber molded products that meet rigorous operational demands.

| Tip | Description | Quality Indicators |

|---|---|---|

| 1. Material Type | Choose the right type of rubber based on application needs. | EPDM, Nitrile, Silicone |

| 2. Duro hardness | Consider the hardness of the rubber for durability. | Shore A scale (30 - 85) |

| 3. Temperature Resistance | Ensure the rubber can withstand required temperatures. | -40°C to +200°C |

| 4. Chemical Resistance | Identify resistance against relevant chemicals. | Acids, Bases, Oils |

| 5. Aging Properties | Evaluate how the material ages over time under stress. | Cracking, Hardening |

| 6. Flexibility | Check the flexibility needed for product usage. | Elasticity and Bend Test |

| 7. Surface Finish | Assess the importance of surface texture and finish. | Smooth, Textured, Glossy |

| 8. Color Properties | Consider the aesthetic color requirements for the product. | Custom Colors Available |

| 9. Certifications | Ensure products meet industry-specific certifications. | ISO, FDA, RoHS |

| 10. Supplier Reputation | Research the supplier's history and product feedback. | Customer Reviews, Longevity |

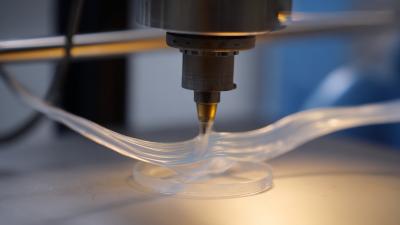

When selecting quality rubber molded products, understanding the manufacturing processes that lead to their creation is crucial. Precision in these processes not only impacts the final product's functionality but also ensures durability and performance. Various manufacturing techniques, such as compression molding, injection molding, and transfer molding, each necessitate strict adherence to standards to guarantee the desired outcomes. Precision in temperature control, timing, and material consistency during these processes allows for uniformity, which is essential for high-quality rubber molded products.

Standards play a pivotal role in the manufacturing of rubber molded goods. Regulatory bodies and industry standards dictate the parameters that manufacturers must follow to ensure safety and reliability. By analyzing these standards, consumers can gauge a manufacturer’s commitment to quality. Effective quality control measures during production, including regular checks and audits, further reinforce the integrity of the molding processes. Consequently, selecting a manufacturer who prioritizes precision and adheres to recognized standards can significantly influence the quality and longevity of rubber molded products.

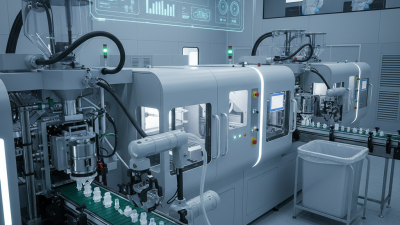

When evaluating suppliers for rubber molded products, the supplier's experience and reputation stand as critical indicators of quality and reliability. According to a recent report by MarketsandMarkets, the global rubber molding market is expected to grow to $10.4 billion by 2025, underscoring the industry's competitive nature. In such a landscape, an experienced supplier with a track record of delivering quality products often signifies greater stability and technical expertise. Companies with over 10 years of experience in the industry are typically more adept at understanding customer needs, adapting to market changes, and implementing advanced manufacturing technologies.

Furthermore, assessing a supplier's reputation involves examining customer reviews, certifications, and industry affiliations. A study by Research and Markets highlights that 70% of consumers prefer suppliers with industry certifications like ISO 9001, which demonstrate a commitment to quality management. Suppliers who actively participate in industry associations often have access to the latest technological advancements and best practices, which can directly improve product quality. Engaging with former clients and seeking out testimonials can also provide insights into the supplier's service reliability and product performance, making these factors essential in the selection process for rubber molded products.

When selecting rubber molded products, understanding their durability and reliability is paramount. The assessment of product performance should involve a series of rigorous tests aimed at ensuring the materials can withstand various stresses. One effective method is the tensile strength test, which measures how much force a rubber product can endure before breaking.

This test provides insights into the elasticity and resistance of the material, crucial for products that will experience heavy use.

Additionally, flexibility and aging tests are essential for evaluating the long-term reliability of rubber molded products. The flexibility test examines how well the product can bend or stretch without cracking, ensuring it is suitable for applications that require movement. Aging tests, which simulate prolonged exposure to heat, ozone, and UV light, help determine how the product will hold up over time. By incorporating these testing protocols, consumers can make informed decisions, ensuring their chosen rubber products meet the necessary performance standards for durability and reliability in their intended applications.