In the ever-evolving world of manufacturing and design, the art of casting plastic has emerged as a versatile technique that allows creators to bring their imaginative visions to life. According to industry expert Dr. Emily Carter, a leading specialist in polymer engineering, "The potential of casting plastic lies not only in its flexibility and strength but also in its ability to replicate intricate designs with precision." This statement underscores the importance of mastering the fundamentals of plastic casting for anyone looking to explore this fascinating field.

For beginners, understanding the basic principles and techniques of casting plastic can be a transformative experience. Whether you are designing prototypes, creating art pieces, or developing functional components, effective casting techniques can greatly enhance the quality and efficiency of your work. As we delve into the tips and best practices for successful casting plastic, we will explore essential aspects such as mold preparation, material selection, and curing processes, each critical to achieving desired outcomes. By equipping yourself with this knowledge, you can start your journey into the world of plastic casting with confidence and creativity.

Plastic casting is a fascinating art form that invites creativity and precision. For beginners, understanding the foundational principles is crucial to achieving successful results. At its core, plastic casting involves creating a mold into which liquid plastic is poured. This process transforms the liquid into solid shapes, making it an ideal technique for producing various items, from decorative pieces to functional components. Newbies should start by familiarizing themselves with the different types of plastics available and their properties, as this knowledge will guide the selection of materials suited to their projects.

When embarking on a plastic casting journey, safety precautions are paramount. Beginners should always work in well-ventilated spaces and wear protective gear, such as gloves and masks. The casting process also requires a clear understanding of the mixing ratios and curing times, as improper handling can lead to subpar results. Starting with simple projects, such as casting small shapes or basic molds, can help novices build confidence and hone their skills. As they gain experience, they can experiment with intricate designs and additional techniques, paving the way for more advanced plastic casting endeavors.

When embarking on plastic casting projects, understanding the essential materials and equipment is crucial for achieving successful results. The primary materials required include high-quality casting resins, which are often categorized into two types: urethane and epoxy. Urethane resins are favored for their flexibility and impact resistance, making them ideal for intricate molds. In contrast, epoxy resins are known for their superior adhesion and durability, suitable for projects demanding a high level of finish and strength. According to a market analysis by Research and Markets, the global demand for epoxy resin is expected to grow steadily, driven by advancements in formulation technologies that cater to diverse applications, including art and industrial usage.

In addition to resin, other key elements include hardeners, pigments, and release agents. Hardeners activate the chemical reaction that transforms the liquid resin into a solid state, ensuring proper curing. Pigments enable the customization of colors, allowing creators to produce vibrant, eye-catching pieces. Release agents are critical to ensuring easy demolding, preventing the resin from sticking to the mold surface.

Industry data indicates that about 70% of casting failures can be attributed to improper use of release agents, highlighting their importance in the casting process. The right equipment, such as mixing cups, spatulas, and vacuum chambers, further supports a smooth workflow, ensuring precision and enhancing the overall quality of the finished product.

Preparing your mold is a crucial step in the plastic casting process, particularly for beginners seeking to achieve high-quality results. According to a recent industry report by the Plastic Industry Association, improper mold preparation accounts for nearly 30% of defects in casting processes. Therefore, understanding the fundamentals of mold preparation can significantly enhance the success rate of your projects.

The first step in preparing your mold involves ensuring that it is clean and free from any debris or contaminants. This not only affects the finish of the final product but also the overall casting process. Utilizing a non-abrasive cleaner and inspecting the mold for any wear or damage can prevent issues down the line. Following this, the application of a suitable mold release agent is essential. Research shows that properly applied release agents can reduce the likelihood of sticking and support easier demolding, which is especially beneficial for complex mold designs.

Furthermore, it’s important to properly align and secure your mold halves to prevent leakage during the casting process. Ensuring a tight seal can minimize imperfections and improve the consistency of the finished pieces. Additional techniques, such as using clamps or additional fasteners, can optimize security and prevent any shifting. By following these essential mold preparation steps, beginners can significantly improve their casting efficiency, leading to more successful outcomes in their projects.

When pouring and curing plastic, it's essential to follow key techniques to ensure safe and effective results. One fundamental tip is to always work in a well-ventilated area. This helps minimize exposure to potentially harmful fumes that can be released during the mixing and curing process. Additionally, wearing protective gear such as gloves and safety goggles is crucial for safeguarding your skin and eyes from any splashes or irritants.

Another important technique is to measure your materials accurately. Precision is vital in achieving the right consistency and curing properties of the plastic. Use a digital scale for precise measurements and follow the instructions closely to avoid problems during the casting process. Before pouring, ensure that the mold is clean and dry to prevent any contamination, which could compromise the final product’s quality.

Lastly, patience is key when it comes to the curing process. Allow the plastic sufficient time to cure fully before demolding, as rushing this step can lead to uneven results or weakened structure. It might be helpful to set a timer or mark the curing time on your calendar to stay organized. By adhering to these techniques, you can enhance the effectiveness and safety of your plastic casting projects.

| Technique | Description | Safety Tips |

|---|---|---|

| Mold Preparation | Ensure molds are clean and coated with release agent to prevent sticking. | Wear gloves and a mask to avoid contact with chemicals. |

| Mixing Ratio | Follow the manufacturer's instructions for resin and hardener ratios. | Use a scale for precise measurements. |

| Pouring Technique | Pour slowly into the lowest part of the mold to avoid air bubbles. | Work in a well-ventilated area to minimize fumes. |

| Curing Process | Allow the plastic to cure completely as per the specifications to achieve the best results. | Keep away from direct sunlight and maintain a stable temperature. |

| Post-Processing | Trim, sand, and polish your cast piece after proper curing. | Use a dust mask during sanding to avoid inhaling particles. |

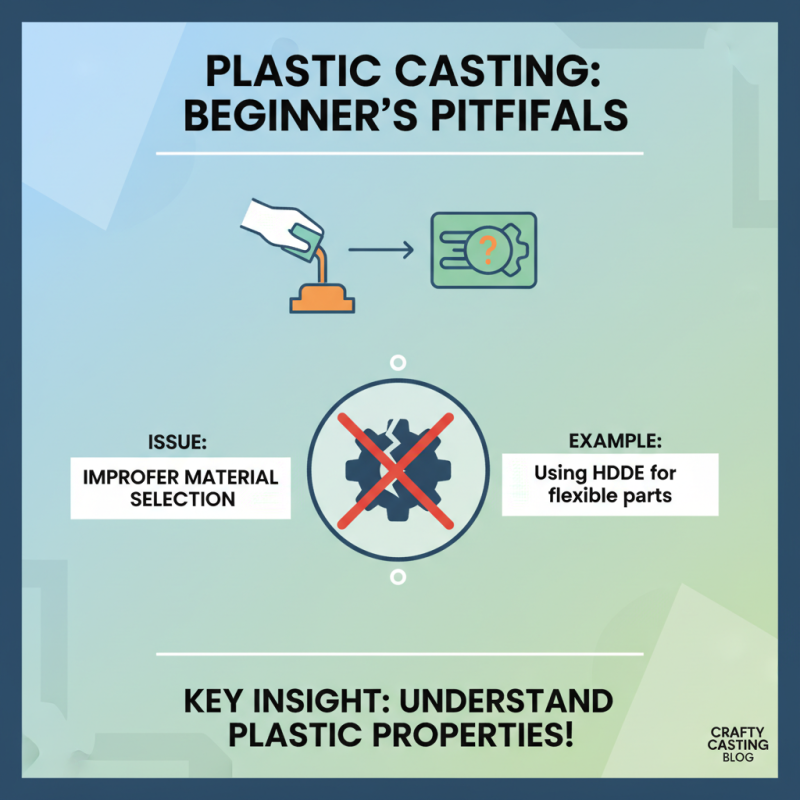

When it comes to plastic casting, beginners often face common pitfalls that can hinder their progress and affect the quality of their work. One prevalent issue is improper material selection. Understanding the properties of various plastics is crucial; for instance, using a high-density polyethylene (HDPE) for applications that require more flexibility is a frequent mistake. According to a report by the Plastics Industry Association, 30% of new crafters struggle with material choices, resulting in failed projects and wasted resources. Familiarizing oneself with the different types of plastics available and their specific uses can greatly enhance the outcomes of casting endeavors.

Another common error is inaccurate measurement of materials. Many novice casters underestimate the importance of precise ratios, leading to poor chemical reactions and incomplete curing. The American Chemistry Council emphasizes that achieving an accurate mixture is vital for optimal performance and longevity of the final product. It’s recommended that beginners invest in a reliable scale and practice measuring to develop a keen eye for proportions. Furthermore, the environment in which casting takes place can also influence results; controlling temperature and humidity can prevent issues like surface defects and bubbles, which are frequent in unregulated conditions. By addressing these pitfalls, novice plastic casters can build a solid foundation for their crafting skills.