When embarking on DIY projects, one important decision involves selecting the right plastic tubes. These versatile materials come in various shapes, sizes, and colors. Choosing the wrong type can lead to frustration. Without careful thought, your project may not meet its intended purpose.

Plastic tubes serve numerous applications, from crafting to structural uses. They can be lightweight or sturdy, depending on what you need. Think about the specific requirements of your project. Will the tube need to bend or hold weight? Use your imagination to envision the final product. However, it's not always straightforward. Not all plastic tubes are created equal, and mistakes can happen.

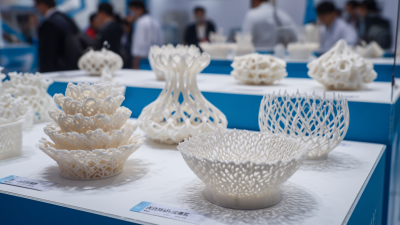

Considering both functionality and aesthetics is crucial. Some projects require clear tubes for visibility, while others benefit from colored options for design. Sometimes, it seems easier to pick any available option. But reflecting on your choices can lead to better outcomes. Take your time to understand the differences among plastic tubes before you leap into action.

When selecting plastic tubes for your DIY projects, it’s important to understand the various types available.

Plastic tubes come in many shapes and sizes, each suited for different applications.

PVC, for instance, is well-known for its strength and durability.

These tubes are often used in construction and plumbing.

Yet, flexibility is key in some cases. Here, silicone tubes excel; they can withstand high temperatures and adapt to various shapes.

Tips for choosing the right tube include considering your project's temperature and chemical exposure.

Think about where and how you will use the tube.

If you require a tube that bends easily, opt for flexible options. Conversely, if you need rigidity, harder types may be ideal.

However, it's easy to overlook certain aspects. Ensure the tube fits your project's specific needs.

Some tubes may seem suitable but lack durability. Also, remember to check wall thickness.

A thinner wall may be cheaper but can be less reliable. Balancing cost and quality is essential.

Consider your long-term goals, not just immediate results.

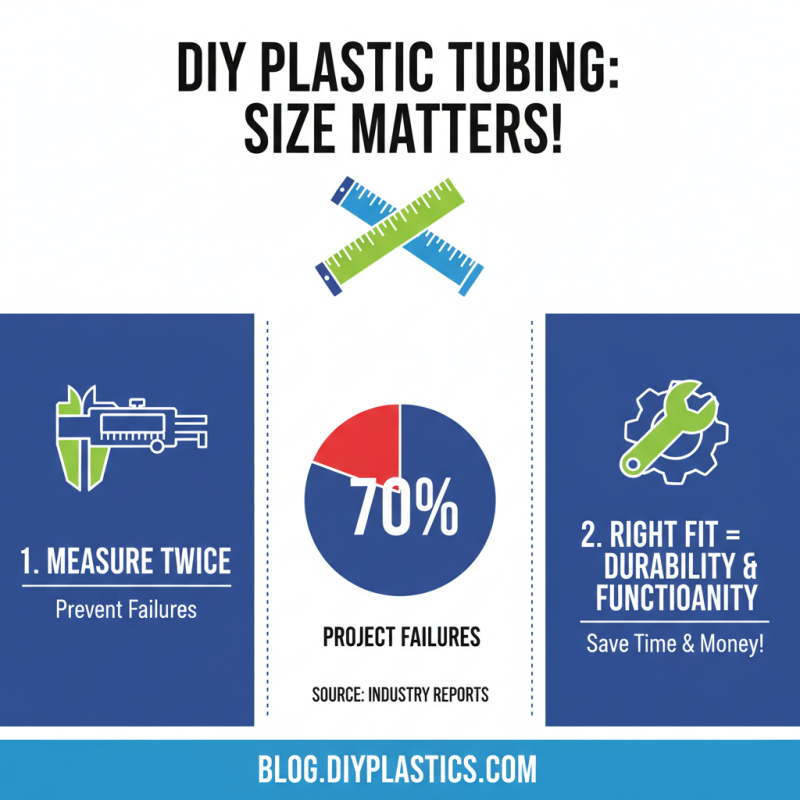

When choosing plastic tubes for DIY projects, size and dimensions are crucial. The right fit ensures functionality and durability. According to industry reports, over 70% of project failures occur due to improper sizing of materials. Selecting tubes that don’t match your intended use can lead to issues. Measure twice, cut once.

Consider your project requirements carefully. The diameter of the tube affects flow and pressure. A tube that is too narrow may restrict movement, while one that is too wide may lack support. Reports by the Plastics Industry Association indicate that precise dimensions can enhance the performance of a project by up to 50%. Pay attention to wall thickness too. A thicker wall can provide better stability but may add unwanted weight.

Many DIY enthusiasts overlook these details. It’s easy to assume one size fits all. However, choosing the wrong dimensions can lead to wasted materials and time. Reflecting on the specific needs of your project can make a significant difference. Always validate measurements and consider potential adjustments. There is no one-size-fits-all solution; your individual project will dictate what works best.

When selecting plastic tubes for DIY projects, material properties play a crucial role. Different plastics offer varying degrees of strength, flexibility, and durability. For example, polyvinyl chloride (PVC) is known for its rigidity and chemical resistance, making it suitable for plumbing applications. In contrast, polyethylene is lightweight and impact-resistant, ideal for storage solutions. According to recent industry reports, these materials are used in up to 80% of custom tubing applications.

However, not all plastics perform equally under stress. For instance, certain types of polyethylene may become brittle at low temperatures, compromising their integrity. Research indicates that over 60% of DIY enthusiasts face performance issues due to material selection. This underscores the need to evaluate each project's demands closely. Users often overlook the importance of environmental factors, such as temperature and exposure to chemicals, which can affect performance. Keeping these details in mind can lead to more successful and long-lasting projects.

| Material Type | Flexibility | Durability | Temperature Range (°C) | Applications |

|---|---|---|---|---|

| Polyethylene (PE) | Moderate | Good | -50 to 80 | Water pipes, bottles |

| Polyvinyl Chloride (PVC) | Rigid | Excellent | -15 to 60 | Drainage, electrical conduit |

| Polypropylene (PP) | Flexible | Very Good | -20 to 100 | Food containers, laboratory tubes |

| Acrylic (PMMA) | Brittle | Good | -40 to 70 | Display cases, aquariums |

| Polystyrene (PS) | Brittle | Moderate | -20 to 70 | Packaging, disposable items |

When selecting plastic tubes for DIY projects, flexibility is a key factor to consider.

Flexible tubes work well for applications requiring bends and turns. They easily navigate around obstacles, which makes them ideal for intricate designs. However, too much flexibility might compromise stability. Finding a balance is crucial.

Look for tubes that retain shape while allowing some movement.

Strength is another important aspect. Tubes need to withstand pressure, weight, or external forces. Thicker walls can improve strength, but they may reduce flexibility. Testing different thicknesses can help determine the best fit for your project. It’s also beneficial to consider the material. Some plastics, like PVC, are inherently stronger than others.

Durability is essential for long-term use. Tubes should resist environmental factors, like UV light and moisture. Choosing the right material can enhance longevity.

However, remember that some options may be more expensive. Weighing cost against performance is vital.

Explore various tubes to see what fits your needs. Reflection on your specific application will guide your decision. It’s a learning process, and it may take time to find the perfect option.

When planning DIY projects, budgeting is crucial. Quality plastic tubes can vary significantly in price, impacting your overall budget. Start by outlining your project's requirements. Think about length, diameter, and type of plastic. These factors affect both performance and cost.

Tips for budgeting include exploring local suppliers. Often, small stores offer better deals than large retailers. Check online marketplaces too. Sometimes, bulk purchases can save you money. Make a list of the specifications needed, so you're not swayed by flashy advertisements.

Also, consider the environmental impact of your choices. Recycling and reusing materials can help you stay within budget and be eco-friendly. Look for options that might not be perfect but serve your purpose. Hasty decisions can lead to wasted resources. Take your time, compare prices, and ensure you're sourcing quality tubes without overspending.