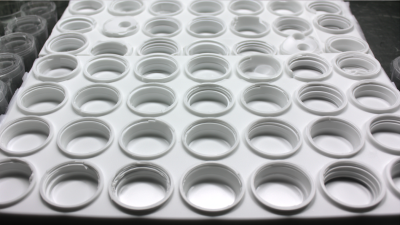

When embarking on a new project, choosing the right plastic parts is crucial. The quality of these components can significantly impact your project’s success. Plastic parts come in various types, each serving a different purpose. Selecting the appropriate materials can seem overwhelming.

Consider the specific requirements of your project. Are you looking for durability, flexibility, or aesthetic appeal? Each plastic type offers unique characteristics. For instance, ABS is strong and tough, while PVC is widely used for its flexibility. Reflect on the environment in which these parts will function. Will they face extreme temperatures or exposure to chemicals?

It's natural to feel uncertain when making such decisions. Mistakes can lead to delays and increased costs. Try to gather as much information as possible. Consult with experts or use reliable resources. Your choices today can have lasting effects on the overall outcome of your project. Remember, even minor adjustments in selecting plastic parts can lead to significant improvements down the road.

Choosing the right plastic material is crucial for project success. Numerous types exist, each with unique properties. Polypropylene (PP) is lightweight and resistant to chemicals. It is widely used in packaging and automotive parts. According to a 2022 report from Plastics Industry Association, PP accounts for 19% of global plastic usage.

Polyethylene (PE) offers excellent flexibility and durability. It's commonly used in bags and bottles. Data indicates that PE production reached 100 million tons in 2022. Meanwhile, polyvinyl chloride (PVC) is known for its rigidity. It's often found in construction materials. However, it can pose environmental challenges.

Despite the variety, choosing material requires careful consideration. Each plastic has specific benefits and limitations. The production process impacts its strength and longevity. Understanding these factors helps avoid costly mistakes. For example, using a brittle plastic in high-stress applications can lead to failures. Assessing project requirements is essential. Make sure to weigh the pros and cons. The right choice makes all the difference.

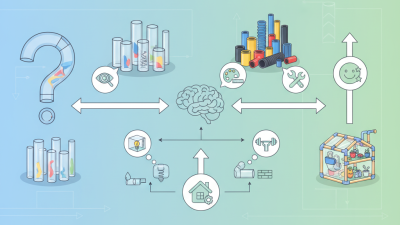

When selecting plastic parts for your project, it's crucial to keep several key factors in mind. Consider the material type. Different plastics offer various properties. For example, some are flexible while others are rigid. Think about the environment where the parts will be used. Exposure to heat, moisture, or chemicals can impact performance. Also, review mechanical properties. Strength, durability, and resistance to wear can be critical for success.

Sizing and tolerances play a major role. Inaccurate dimensions can lead to assembly issues. It’s essential to measure accurately. Look into the manufacturing process, too. Techniques like injection molding or 3D printing can affect both quality and cost.

Lastly, consider the aesthetics. Color and finish might seem trivial, but they impact overall appeal. Reflect on how the parts will be perceived. It’s easy to overlook these details in the rush to complete a project. Taking time to evaluate these factors can save complications down the line. Designing with intent makes a difference.

| Criteria | Description | Examples |

|---|---|---|

| Material Type | Consider the specific properties needed such as strength, flexibility, or durability. | ABS, Polycarbonate, Nylon |

| Mechanical Properties | Evaluate tensile strength, impact resistance, and stiffness required for your application. | Tensile Strength, Elongation Percentage |

| Temperature Resistance | Check the working temperature range and thermal stability of the materials. | Polystyrene (PS), Polypropylene (PP) |

| Chemical Resistance | Ensure that the plastic can withstand the chemicals it may come in contact with. | Polyethylene (PE), PVC |

| Cost and Availability | Consider budget constraints and the availability of materials in the market. | Local Suppliers, Bulk Purchases |

When choosing plastic parts, mechanical and thermal properties are crucial. Each project has unique demands, which plastics must meet. For example, tensile strength will impact how a part withstands forces. If the part is used in a load-bearing application, consider a plastic with high tensile strength.

Thermal properties also matter. Some plastics can tolerate high temperatures without losing integrity. Others may warp or bend if they get too hot. Before starting, assess the working environment of your parts. Will they be exposed to heat or cold? This evaluation will help in selecting the right type.

Tips: Check the thermal conductivity of each plastic. Some materials dissipate heat better than others. Also, remember that certain plastics may degrade faster under UV light. This can lead to premature failures in outdoor applications. Always consider the long-term implications of your choice. A little extra research can save headaches later.

When evaluating plastic components for your project, cost-effectiveness is a key factor. Quality materials can vary significantly in price. It’s essential to compare options. Look for suppliers who provide transparent pricing. Reading customer reviews can help gauge quality versus cost. Consider bulk purchasing for savings, but ensure it aligns with your project needs.

Availability is another critical aspect. Some plastics have long lead times. This can delay your project schedule. Verify stock levels before making commitments. Prioritize suppliers with a reliable inventory. Local suppliers may offer quicker access, yet global suppliers might have unique options at competitive prices. Stay flexible in your choices. A less common type might save costs, even if it’s not your first option. Weigh the trade-offs carefully.

When considering sustainability in choosing plastic for your project, understanding material options is crucial. The global plastic market is projected to reach 1.5 trillion USD by 2025, highlighting the need for eco-friendly alternatives. Bioplastics, for instance, can reduce carbon footprints significantly. Reports indicate that using bioplastics can lower greenhouse gas emissions by up to 50% compared to conventional plastics.

Tips: Look for certifications. Materials like PLA are often labeled as compostable. This helps in making informed choices. Recycling potential also matters. The recycling rate for plastics is only about 9% globally. Choose materials that are easier to recycle to contribute to circular economies.

It’s essential to reflect on production processes. Oil-based plastics consume vast resources and contribute to pollution. A 2019 study revealed that plastic waste could surpass fish in oceans by 2050. This is a reminder of the impact our choices make. Ask yourself: Are there alternative materials that can fit your requirements? Balancing performance and sustainability is key.