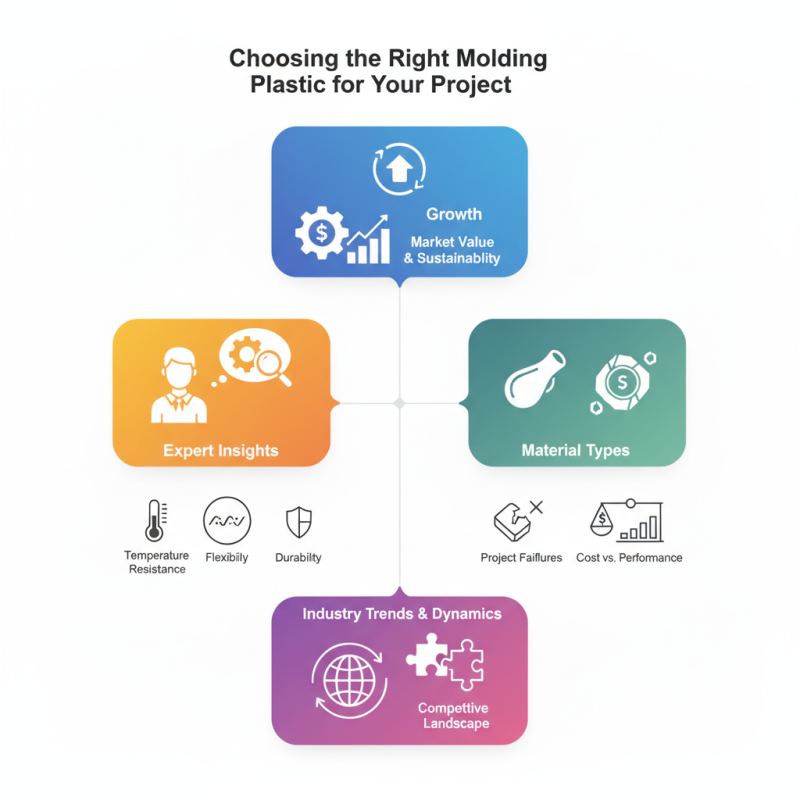

Choosing the right molding plastic for your project can be challenging. With numerous options available, making an informed decision is crucial. According to a report by Grand View Research, the global molding plastic market is expected to reach USD 640 billion by 2027. This growth underlines the importance of selecting the right materials for both quality and sustainability.

Expert Michael Thompson, a leading figure in the plastic industry, emphasizes, “Understanding the properties of each molding plastic type is essential for successful applications.” Different molding plastics offer distinct functionalities. Factors such as temperature resistance, flexibility, and durability play significant roles in material choice.

While many projects call for standard plastics, specialized applications may require unique formulations. Not all molding plastics are created equal, and overlooking material properties can lead to project failures. Striking the right balance between cost and performance is often a reflection of broader industry trends. Understanding these dynamics is vital in today’s competitive landscape.

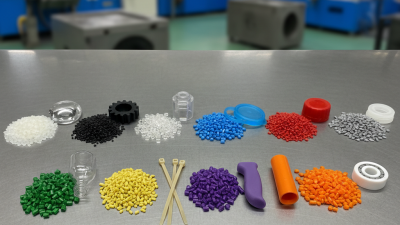

When choosing molding plastics, understanding their types and properties is crucial. Thermoplastics are versatile. They can be repeatedly heated and shaped. Common examples include polycarbonate and acrylic. These materials offer clarity and impact resistance. However, their temperature limits may not suit every application.

On the other hand, thermosets provide excellent heat resistance. Once cured, they cannot be reshaped. Epoxy resins are a typical thermoset, known for strong bonding. They excel in demanding environments. But, this also means working with them requires precise mixing and timing. Mistakes can lead to wasted materials.

Another category is elastomers, known for their flexibility. They can stretch and return to original shapes. They are great for sealing applications. Yet, they often come with trade-offs in durability. Finding the right balance between flexibility and strength can be challenging. Evaluating your project's specific needs helps in making informed choices. Understanding these details may prevent costly errors down the line.

| Type of Molding Plastic | Properties | Best Uses | Melting Point (°C) | Cost (per kg) |

|---|---|---|---|---|

| ABS (Acrylonitrile Butadiene Styrene) | Durable, impact-resistant, easy to machine | Consumer goods, automotive parts, toys | 105-120 | $1.80 |

| PLA (Polylactic Acid) | Biodegradable, low-shrinkage, easy to print | 3D printing, food packaging, coating | 160-180 | $2.00 |

| PET (Polyethylene Terephthalate) | Strong, lightweight, good barrier properties | Bottles, containers, textiles | 250-280 | $1.50 |

| PVC (Polyvinyl Chloride) | Durable, fire-retardant, cost-effective | Pipes, credits, flooring | 75-105 | $0.90 |

| Nylon (Polyamide) | Strong, flexible, wear-resistant | Gears, bearings, industrial applications | 210-260 | $2.50 |

When evaluating project requirements for molding plastics, it's essential to consider several key factors. First, identify the physical and mechanical properties needed. Reports indicate that approximately 45% of project failures result from poor material selection. Strength, flexibility, and temperature resistance are crucial aspects, often overlooked in early stages.

Cost is another important factor. Balancing quality and budget is tricky. Sometimes, opting for a cheaper plastic can lead to higher costs in production or product failure. According to industry analysis, nearly 30% of projects go over budget due to improper materials.

**Tips:** Always test small samples before full production. This can prevent costly mistakes.

Compatibility with existing processes also matters greatly. Different molding techniques require specific plastic types. If the material doesn’t align with your molding method, you might face complications. Seeking advice from experienced professionals can provide valuable insights.

**Tips:** Consult with experts. Their input can save time and money.

Lastly, don't ignore environmental impacts. Sustainable materials are gaining popularity. Choosing eco-friendly options may add upfront costs but can increase market appeal. Balancing all these elements can lead to better choices and successful project outcomes.

When selecting molding plastics for industrial applications, cost and benefits play a significant role. Different materials have unique characteristics that influence both production costs and finished product performance. For instance, thermoplastics often provide flexibility and ease of processing, but they can be pricier compared to other options. Understanding the specific needs of your project is essential for making an informed decision.

Polypropylene is a commonly used material. It's lightweight, resistant to chemicals, and often more cost-effective. However, its mechanical strength may not match that of other plastics, like polycarbonate. Many engineers find themselves grappling with trade-offs. Choosing a material that excels in one area can lead to compromises in another. Evaluating these factors closely can lead to better outcomes.

Another consideration is the production process itself. Injection molding can be efficient but requires high initial investment. On the other hand, simpler methods may save costs but result in lower-quality outcomes. Balancing cost with functionality and durability requires careful assessment. It’s not an easy task, and it may lead manufacturers to rethink their choices frequently.

When selecting molding plastics, temperature and durability stand out as crucial factors. Temperature can significantly affect the performance of plastic. High temperatures may cause some plastics to deform or lose their structural integrity. Low temperatures might lead to brittleness, making the material prone to cracking.

Choosing the right material means assessing the environment where the product will be used. Consider variations in daily temperatures. Ensure the plastic can withstand those changes without failing. It’s important to recognize the limitations of certain plastics. Not all plastics are created equal; some might not cope well under extreme conditions.

Tips: Always test samples before making large orders. This helps to spot potential issues in real-world conditions. Additionally, pay attention to the specific requirements for durability. A plastic that works for one project might not suit another. It’s worth reflecting and asking if the chosen material will stand the test of time. In some cases, you might need to revisit your choices to ensure long-lasting results.

When selecting molding plastics, sustainability is key. Eco-friendly options are gaining traction in the industry. In fact, a report from the Plastics Industry Association reveals that around 75% of consumers prefer products made from sustainable materials. Choosing biodegradable or recycled plastics can significantly reduce environmental impact. These materials often come from renewable resources, making them less harmful.

Life cycle assessments show that traditional plastics contribute to climate change due to greenhouse gas emissions. A study found that using bioplastics can reduce carbon footprints by up to 70%. However, the market still lacks transparency regarding production processes. Consumers are often unaware of the differences between various eco-friendly options.

Not all biodegradable plastics perform equally. Some break down in industrial settings but not in natural environments. This confusion can lead to poor choices in project materials. Designers must investigate the specifics before committing. Balancing performance and sustainability can be challenging, yet worth the effort. Focusing on responsible sourcing is essential. Seeking certifications can guide consumers towards better decisions.