In the ever-evolving world of manufacturing, the significance of selecting the optimal shapes for plastics projects cannot be overstated. According to a recent report by the Plastics Industry Association, the global plastics market is expected to reach $1 trillion by 2025, with a substantial portion of this growth driven by innovative shapes and designs that enhance functionality and aesthetic appeal. As companies strive to meet diverse consumer demands, the choice of shapes plastics takes center stage in determining the overall success of a project.

Industry expert Dr. Emily Chang, a leading figure in polymer engineering, emphasizes the critical nature of this decision: “The geometry of your design can drastically affect not only the manufacturing process but also the product's performance and user experience.” This statement highlights the multifaceted role that design shapes play, influencing everything from production efficiency to marketability. As various industries explore the potential of new materials and shapes, designers and engineers must consider the interplay between shape, function, and manufacturing capabilities to ensure their projects stand out in a competitive marketplace.

Understanding the principles behind shapes plastics is essential for any designer or manufacturer aiming to leverage the advantages of modern materials. From enhancing structural integrity to optimizing production processes, the right shapes can lead to breakthroughs in both design and functionality. As we delve deeper into this topic, it becomes clear that the future of plastics projects depends heavily on informed choices in design shapes.

When it comes to plastics design, the shape of a product plays a crucial role in both functionality and aesthetics. Understanding the importance of shape can significantly enhance a project’s efficiency and marketability. A well-considered shape not only affects the structural integrity of the product but also influences user experience. Whether it’s ergonomic contours for comfort or sleek forms for visual appeal, the choices you make will define the end result.

Tips for selecting shapes include understanding the intended use of the product. For instance, a shape that maximizes mechanical strength might be essential for a part exposed to stress, while a more intricate design might be ideal for decorative purposes. Additionally, consider the manufacturing process; some shapes are easier and more cost-effective to produce than others. Always prototype different shapes during the design phase to evaluate their practical implications before finalizing your choice.

Another important aspect is the market context. The shape should resonate with your target audience, reflecting current trends or timeless designs. Pay attention to what competitors are doing, but always aim to create something unique. Simple shapes can evoke modernity, while complex forms can suggest sophistication. Balancing these elements will help you achieve a successful design that stands out in the market.

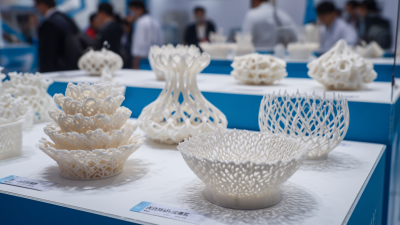

This chart illustrates the distribution of commonly used shapes in plastics projects, showcasing the significance of selecting the right shape for enhancing functionality and aesthetics.

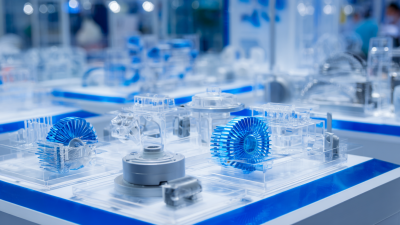

When embarking on plastics projects, selecting the right shapes is crucial for functionality and aesthetics. One of the primary factors to consider is the intended use of the product. Are you designing something for structural integrity, or is the focus on visual appeal? For instance, geometric shapes like squares or rectangles often offer strength and stability for structural applications, while organic shapes may enhance the visual appeal in consumer products. Understanding the application's requirements helps guide the choice of form to ensure the final product meets both practical and design goals.

Another important consideration is the production process. Different shapes can greatly impact the manufacturability of a plastics project. Intricate designs might require advanced techniques that could increase production costs and time. Therefore, choosing simpler shapes might be more efficient and cost-effective, especially for larger production runs. Additionally, compatibility with the chosen molding or extrusion processes should be evaluated to maximize the efficiency of production. Balancing aesthetic desires with practicality in the production process is essential for successful project outcomes.

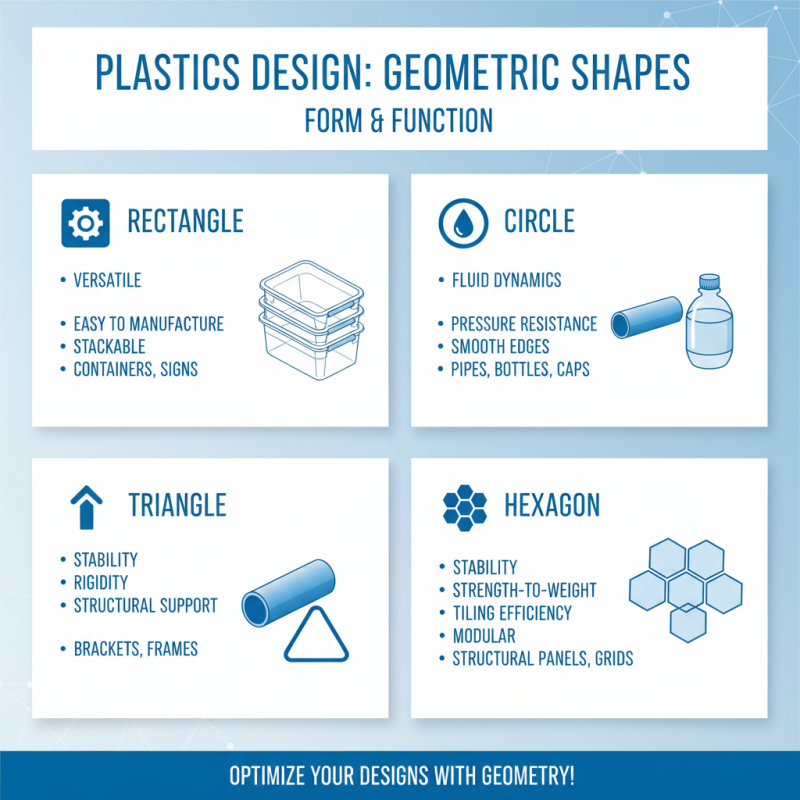

When designing and creating projects with plastics, understanding the common geometric shapes and their applications is crucial. Each shape offers unique benefits, influencing the structural integrity, aesthetic appeal, and functionality of the final product. For instance, the rectangle is one of the most versatile shapes used in plastic design due to its ease of manufacturing and ability to stack efficiently. Rectangular containers, signage, and various structural components benefit from this shape’s straightforward geometry.

Another essential shape is the circle, which is widely used in applications requiring balance and fluid dynamics. Circular components, like gear wheels or caps, are preferred for their ability to distribute stress evenly. Furthermore, the sphere is a shape that finds extensive use in applications ranging from decorative elements to functional parts like balls and bearings, as it minimizes surface area and maximizes strength. Additionally, hexagons are favored in designs that require tessellation, providing optimal space utilization in projects such as honeycomb structures or tile arrangements.

Understanding these shapes and their distinct applications helps designers effectively choose the right geometry for their specific plastic projects, enhancing both function and design. Each geometric form offers different advantages that can significantly impact the performance and aesthetics of the finished product.

When selecting shapes for your plastics projects, striking a balance between aesthetics and functionality is crucial. Aesthetically pleasing shapes can enhance the overall appeal of a product, attracting consumers with their visual charm. Curves and organic forms can evoke feelings of warmth and approachability, while sharp angles and geometric designs often convey modernity and precision. However, the visual impact must not overshadow the practical aspects of the design. It’s essential to ensure that the shapes allow for ease of manufacturing and usability, and that they align with the intended purpose of the product.

Functionality dictates that shapes should also enhance performance and efficiency. For instance, a container designed with a wide base may provide better stability, while an ergonomic handle can improve user experience. The choice of shape can influence factors such as weight distribution, material stress, and even assembly processes. Thus, designers must consider both aesthetic and functional requirements when deciding on shapes, ensuring that each aspect complements the other. By harmoniously integrating beauty and practicality, designers can create innovative plastics projects that stand out in the market.

| Shape | Aesthetic Appeal | Functionality | Common Uses |

|---|---|---|---|

| Square | Highly versatile and modern | Stable for stacking and storage | Containers, boxes, electronics |

| Circle | Elegant and soft appearance | Even weight distribution | Lids, bottles, cups |

| Triangle | Dynamic and modern look | Strong structure and stability | Architectural elements, packaging |

| Hexagon | Unique and eye-catching | Maximizes space efficiency | Tiles, coasters, fitness products |

When it comes to selecting the right shapes for plastics projects, validating these designs through testing and prototyping is crucial. The design process in the plastics industry often includes iterative prototyping to ensure that the chosen shapes not only meet aesthetic standards but also uphold functionality and manufacturability. According to a report by the Society of Plastics Engineers, prototyping can reduce product development time by up to 50%, enabling designers to quickly identify and rectify potential design flaws before full-scale production.

In addition to accelerating the design process, testing can provide essential data that drive material selection and fabrication methods. For instance, shape optimization studies have shown that certain geometrical configurations can enhance the strength-to-weight ratio significantly. Data from the American Society for Testing and Materials indicates that prototypes can reveal critical insights into stress distribution and thermal behavior, allowing designers to refine shapes for improved performance under operational conditions. By leveraging these testing methodologies, designers can validate their shapes against industry standards, ensuring that final products not only meet consumer expectations but also comply with safety regulations.