Choosing the right silicone rubber for your project is crucial. Industry expert Dr. Emily Carter notes, “Selecting the right silicone rubber can make or break your design.” Her insight underscores the importance of informed choices in material selection.

Silicone rubber offers a wide range of properties. It is flexible, durable, and resistant to heat and chemicals. These qualities make it suitable for various applications. However, not all silicone is created equal. Different formulations can yield vastly different results. Many overlook this fact. Selecting the wrong type can lead to failures or unexpected costs.

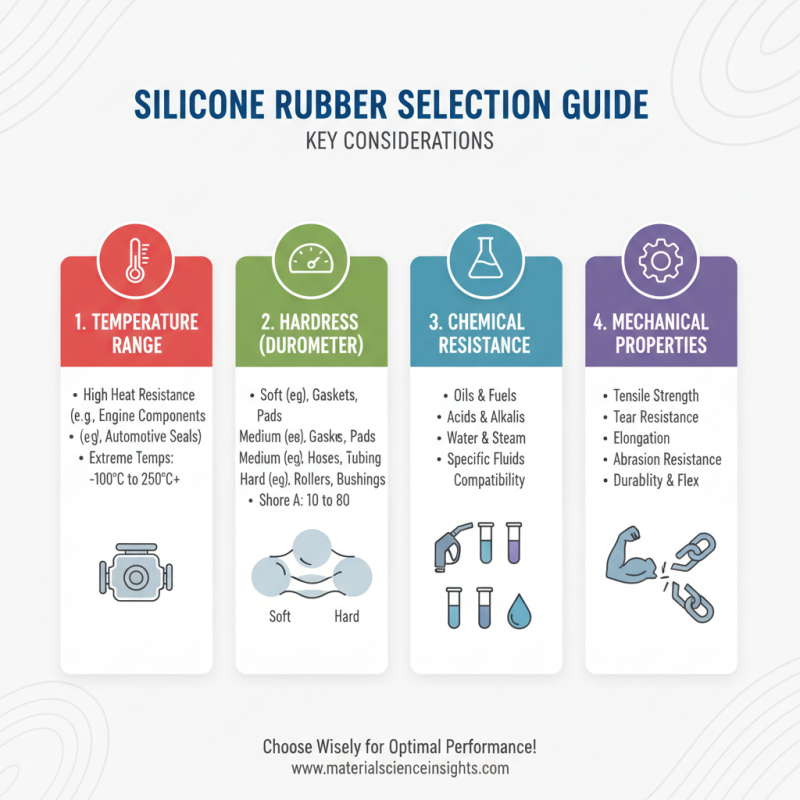

Understanding your project's specific needs is vital. Consider temperature range, flexibility, and exposure to chemicals. Do not rush this decision. Reflect on your objectives and challenges. The right silicone rubber can enhance performance immensely. Yet, the wrong choice may result in disappointment. Take the time to research and explore your options.

Silicone rubber is increasingly popular for various applications. Understanding its core properties is vital for any project. This versatile material is known for its flexibility and resilience. It can endure extreme temperatures, making it suitable for both high and low heat environments. Moreover, it is resistant to UV light and ozone. These features make silicone rubber ideal for outdoor use.

When selecting silicone rubber, consider its durometer, or hardness. This measurement indicates how soft or hard the rubber feels. Softer materials bend easily, while harder options provide more support. Think about how your project might impact the material's performance. Not every formulation will meet your needs perfectly. Some may be too rigid, while others are overly soft for structural components.

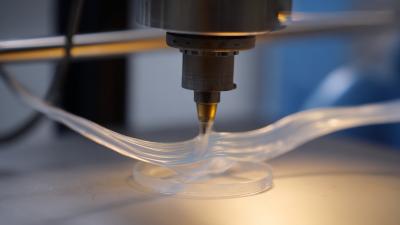

Color can also influence your decision. Silicone rubber comes in various shades, which is great for aesthetics. However, certain pigments might impact the material's durability. The choice can affect longevity over time. Additionally, manufacturing methods differ, which may lead to inconsistencies in texture or performance. You might need to test samples to find what truly works best.

| Property | Description | Application |

|---|---|---|

| Temperature Resistance | Silicone rubber can withstand temperatures ranging from -60°C to 250°C. | Used in automotive seals, gaskets, and cookware. |

| Chemical Resistance | Resistant to many chemicals including acids and bases. | Ideal for medical applications and food processing. |

| Flexibility | Maintains flexibility over a wide temperature range. | Used in flexible components like hoses and seals. |

| Durability | Long-lasting material with excellent weathering properties. | Outdoor applications such as roofing and sealing. |

| Electrical Insulation | Good electrical insulator with high dielectric strength. | Used in electrical connectors and insulators. |

When selecting silicone rubber for your project, consider specific requirements. Start by identifying the temperature range. Some applications need high heat resistance, while others operate in colder environments. For example, automotive parts often face extreme temperatures.

Next, focus on mechanical properties. Understand the tensile strength and flexibility required for your application. For a wearable device, you may prefer softer materials that stretch and bend easily. These details can influence comfort and effectiveness.

Finally, evaluating chemical exposure is vital. Some silicone rubbers resist oils and solvents well, making them ideal for industrial applications. Yet, certain projects may encounter unique chemicals that require careful consideration. Sometimes it’s easy to overlook these factors, leading to potential failures down the line.

When considering silicone rubber for your project, it's essential to compare different types. Silicone rubber comes in various formulations, including high-temperature, medical-grade, and food-safe options. Each type offers specific properties, making them suitable for distinct applications. According to industry reports, the global silicone rubber market is projected to reach over $10 billion by 2026, highlighting its increasing importance in many sectors.

High-temperature silicone rubber is ideal for automotive and industrial uses. This type can withstand temperatures up to 315°C. Medical-grade silicone rubber is necessary for healthcare applications, offering biocompatibility and resistance to sterilization. In contrast, food-safe silicone rubber adheres to health standards, making it perfect for culinary applications.

Tips: Always check for certification labels. They ensure quality and safety. Evaluate the durometer scale. It indicates hardness, affecting flexibility. Not all silicone types are interchangeable. Understand your specific needs before making a selection.

Choosing the right silicone rubber involves assessing these crucial factors. Performance often varies wildly; a mismatch can lead to project failure. Sometimes, it’s easy to overlook minor specifications like temperature resistance or flexibility. Always dig deeper to find the best fit.

When selecting the right silicone rubber, evaluating performance characteristics is crucial. Look at factors like tensile strength, tear resistance, and temperature tolerance. These traits define how the material will function under stress. For instance, high tensile strength ensures durability, while excellent tear resistance prevents failure in critical applications. Pay attention to the specified operating temperature range. Materials that break down in extreme conditions are not suitable.

Durability is another essential aspect. How long will the silicone rubber last? This question requires examining environmental resistance. Some formulations withstand sunlight and ozone, while others degrade quickly. Testing in real-world conditions may reveal unexpected weaknesses. Sometimes, a seemingly ideal choice fails when exposed to moisture. Performance can vary widely based on the manufacturing process, so inspections are vital. Consider the end-use application, as this directly impacts feature selection. A perfect solution might not exist, leading to necessary compromises. These reflections on durability and performance can guide you to a more informed decision.

Selecting the right silicone rubber involves understanding cost and availability. According to a report by MarketsandMarkets, the silicone elastomers market is projected to reach $12.12 billion by 2026. This growth reflects increasing demand across various industries, such as automotive and healthcare. However, deciding based purely on price may lead to issues later. Cheaper options often compromise quality.

When evaluating availability, consider local suppliers and lead times. If a specific grade of silicone rubber is not readily available, it can delay production. In some cases, imported materials may face tariffs or shipping issues, adding unexpected costs. It's crucial to compare local and international sources for the best balance of cost and reliability.

Moreover, be mindful of different grades and formulations. Some specialized silicones can be more expensive but offer superior performance. A lower upfront cost may lead to greater expenses down the line due to failures. It’s essential to weigh short-term savings against long-term outcomes. Balancing these factors is not straightforward and requires careful reflection on project requirements.