In the fast-evolving world of manufacturing, selecting the right plastic for molding is paramount. The global plastic molding market exceeded $600 billion in 2022, highlighting the significance of material choice. Industries like automotive and consumer goods rely heavily on quality plastics. The right plastic can enhance durability, reduce costs, and optimize production time.

Common choices include polypropylene and polycarbonate, each with unique properties. Polypropylene, known for its lightweight nature and resistance to chemicals, is ideal for various applications. Meanwhile, polycarbonate offers superior impact resistance, but can be more expensive. Choosing the wrong plastic can lead to production failures or increased costs.

Many manufacturers still struggle with material selection. Reports indicate that nearly 30% of production issues stem from inappropriate plastic choice. This highlights the need for a thorough understanding of specific requirements for each molding application. Only then can one confidently select the best plastic for molding to meet both functional and economic demands.

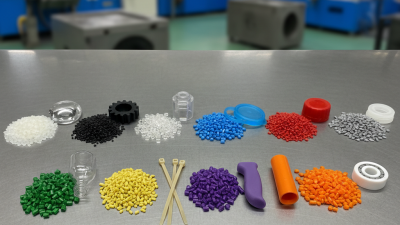

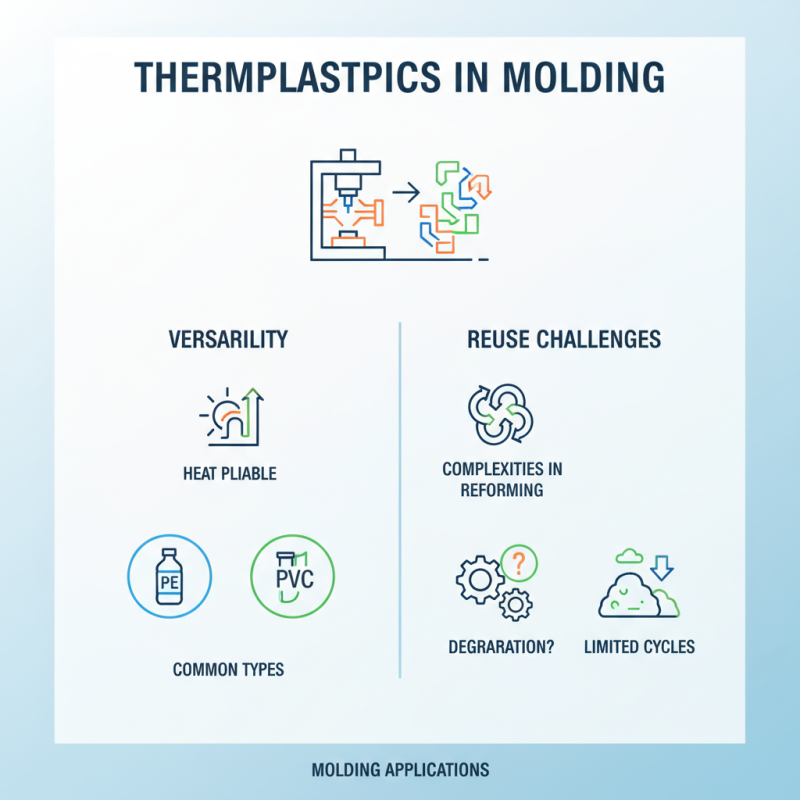

When it comes to molding applications, various types of plastics serve distinct purposes. Thermoplastics, for example, are widely used due to their versatility. They become pliable when heated, allowing for easy shaping and reforming. Common examples include polyethylene and polyvinyl chloride (PVC). These materials are favored in many industries, but they can also present challenges during reuse.

In contrast, thermosetting plastics are selected for their durability. Once set, they cannot be remolded. Epoxy and polyurethane are prime examples. These materials excel in applications requiring strong structural integrity. However, their rigidity might limit flexibility in design.

While the choice of plastic is crucial, it is not always straightforward. Each type comes with specific advantages and drawbacks. A thorough understanding of material properties remains essential. This can lead to reflection on how best to optimize performance while minimizing waste. Factors like cost, environmental impact, and application needs should guide the final decision.

When selecting plastic for molding applications, several key properties must be considered. One crucial factor is the material's strength. A strong plastic can withstand stress during the molding process. It also impacts the durability of the final product. Hard plastics like polycarbonate provide great strength, but they can be challenging to work with.

Another important property is thermal stability. Plastics must resist deformation when exposed to heat. This characteristic is vital during the molding phase where high temperatures are common. For instance, ABS is known for its good heat resistance, making it a popular choice among many manufacturers.

Flexibility can’t be overlooked either. Some designs require a degree of flexibility. A plastic that is too rigid may lead to cracking. Evaluating the weight and density of the plastic is equally important. A lighter material can reduce shipping costs but may compromise strength. Finding the balance is often tricky and requires careful consideration.

When choosing the right plastic for molding applications, different types serve various needs. Common options include ABS, polypropylene, and polycarbonate, each with unique properties. ABS is known for its toughness and impact resistance, making it a favorite for consumer products. Polypropylene, on the other hand, is lightweight and offers excellent chemical resistance, ideal for packaging solutions. Polycarbonate is strong and transparent, perfect for applications requiring transparency and durability.

**Tip:** Understand the specific requirements of your project. Consider factors such as temperature, weight, and environmental exposure when selecting your material. This will save you time and costly errors.

Evaluating these plastics involves not just their strengths but also their weaknesses. ABS can be sensitive to UV light, which might degrade its quality over time. Polypropylene isn't as strong as other alternatives and can warp under high temperatures. Polycarbonate, while strong, is more expensive and might scratch easily. Balancing these considerations is essential for a successful outcome.

**Tip:** Test prototypes before full production. This can reveal unexpected issues with material performance. It’s also a good opportunity to refine your design and avoid costly mistakes later.

When it comes to molding plastics, different materials serve specific industries effectively. For instance,

polypropylene is popular in consumer goods. It's affordable

and durable. Many companies use it for containers and packaging. Its lightweight nature also

makes it suitable for automotive parts.

In contrast, polycarbonate offers superior heat resistance,

making it ideal for electronics and safety equipment. This plastic can withstand higher temperatures without

losing integrity. However, manufacturing polycarbonate can be complex. Some may face challenges in achieving

the right clarity or thickness.

Acrylics are widely used for signage and display materials due to their

transparency and glossy finish. Still, they can be brittle and prone to scratching. Designers must

balance aesthetics with functionality. The choice of plastic ultimately hinges on the application requirements

and potential trade-offs. Each type of plastic has unique strengths and weaknesses that warrant consideration.

The future of plastic materials in molding technologies is promising. Innovations are emerging daily. Researchers are focusing on bio-based plastics and recycled materials. These alternatives aim to reduce environmental impact. Bio-plastics, made from natural sources, offer a renewable option. However, they often lack the performance of traditional plastics.

Another trend is the development of advanced additives. These can enhance the properties of standard plastics. For instance, adding nanoparticles can increase strength and flexibility. This approach shows potential, but it comes with challenges. Balancing performance and cost is not easy. Sometimes, stronger materials can lead to more complicated production processes.

Furthermore, the demand for lightweight components is rising. Industries are seeking solutions to make products lighter without sacrificing quality. Innovations in thermoplastics and composites are responding to this need. Yet, the long-term effects of these materials require careful assessment. It's essential to monitor their environmental footprint as they gain popularity. Adopting new technologies may be necessary, but it also demands reflection on sustainability.