In the realm of protective coatings, plastisol dip coating stands out for its durability and versatility. Industry expert John Smith, a leading figure in the coating sector, remarked, "Plastisol dip coating provides a unique balance of aesthetics and longevity." This method involves immersing an object into a liquid plastisol, which forms a thick and robust layer as it cools. This finish not only enhances the item's appearance but also protects it from harsh environments.

Many industries benefit from plastisol dip coating. It is commonly used in automotive parts, tools, and outdoor furniture. The coating can withstand temperatures and resist chipping, scratches, and corrosion. However, the process is not without its challenges. For instance, achieving a uniform coat can be tricky, requiring skilled technicians to manage the dip and cure times carefully.

While plastisol dip coating offers significant advantages, it is essential for companies to weigh the initial costs against the long-term benefits. The process may be more expensive upfront, but the durability can lead to savings over time. Ultimately, making informed decisions in the coating industry is crucial for lasting success.

Plastisol dip coating is gaining traction in various industries due to its unique properties. It involves immersing objects in a liquid plastisol, which then forms a thick, durable layer upon cooling. One key characteristic is its excellent resistance to corrosion and chemicals. According to the Plastics Industry Association, products coated with plastisol can last 20-30% longer than traditional coatings in harsh environments.

The application of plastisol also offers considerable customization. It can be formulated to achieve different textures and colors. This versatility is appealing for manufacturers looking to enhance the aesthetic appeal of their products. A report from the American Coatings Association reveals that interest in plastisol has surged, with over 60% of manufacturers considering it for new projects. However, achieving the perfect finish can pose challenges. Variability in application techniques may lead to thick or uneven coatings that require rework.

Another appealing trait is its thermal insulation capability. Plastisol coated items stay cooler under high temperatures, which is essential for safety. Yet, the energy cost of heating and maintaining the plastisol bath can be a point of concern. While plastisol dip coating offers many benefits, careful management of resources is vital to avoid increased operational costs.

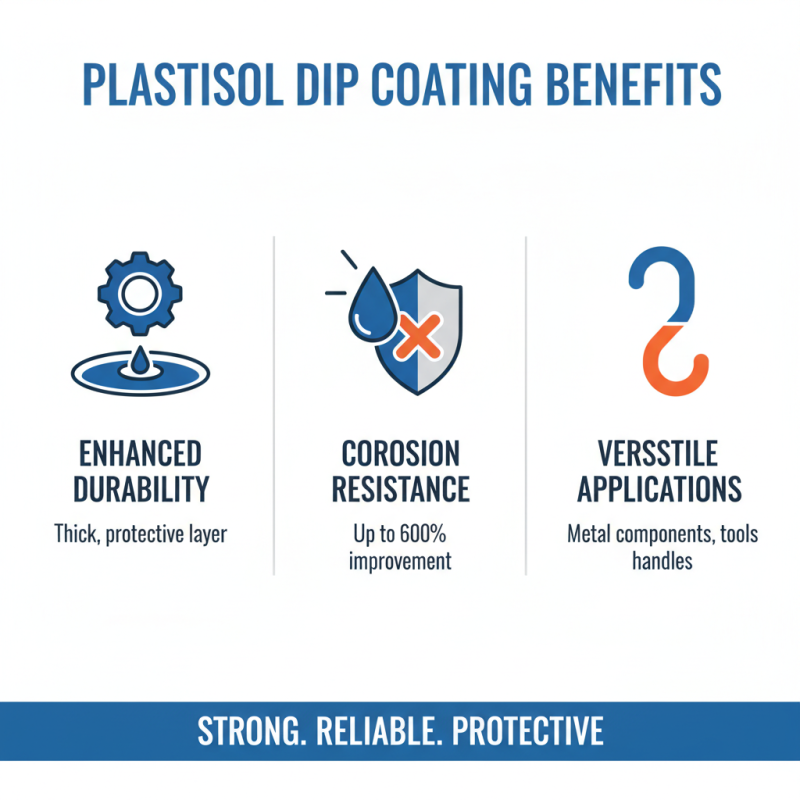

The chart below illustrates the key benefits of Plastisol dip coating, measured by their significance based on industry feedback. Each advantage is represented as a percentage reflecting the importance of durability, flexibility, and corrosion resistance in various applications.

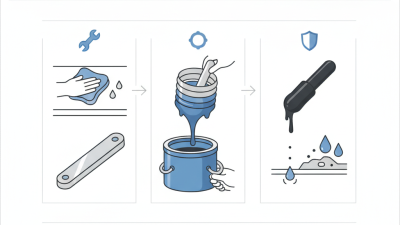

The application of plastisol dip coating involves several precise stages. Initially, materials that require coating are prepped thoroughly. This includes cleaning the surface to remove any contaminants. Industry reports indicate that pre-cleaning can enhance adhesion by up to 30%. After preparation, the items are immersed in a heated plastisol bath. The temperature typically ranges between 375°F to 400°F. This heat allows the PVC particles to fuse, forming a durable layer.

Upon removal from the bath, excess plastisol is drained off, allowing the coated items to cool. A secondary curing process often follows. This step solidifies the coating further, enhancing its resilience. It’s essential to monitor curing times accurately; even slight discrepancies can lead to a weaker finish. Various studies show that over-curing can degrade the surface's appearance, while under-curing can compromise its durability.

The entire process requires skill and attention to detail. Temperature fluctuations can affect the final outcome. Moreover, the choice of plastisol formula plays a critical role. Not all formulations yield the same results. Some might offer better flexibility, while others may provide enhanced resistance to chemicals. Balancing these factors is vital for achieving the desired quality and performance.

Plastisol dip coating offers significant strength and durability for various applications. This coating method involves immersing an item in a liquid plastisol, which forms a thick, protective layer once heated. Reports suggest that plastisol coatings can enhance corrosion resistance by up to 600%. This is particularly beneficial for metal components exposed to harsh conditions.

In addition to corrosion resistance, plastisol coatings provide excellent impact resistance. A 2022 study revealed that parts coated with plastisol showed 80% less damage when subjected to impact tests compared to untreated items. This durability prolongs the lifespan of the products, reducing the need for frequent replacements. The flexibility of plastisol allows it to withstand expansion and contraction without cracking.

However, it’s essential to consider the environmental impact of plastisol coatings. While they offer numerous benefits, the manufacturing process can produce hazardous waste. Additionally, the disposal of coated items may pose challenges. Industries must explore sustainable practices to mitigate these concerns. Balancing performance and environmental responsibility remains a complex challenge in utilizing this coating technology effectively.

Plastisol dip coating has gained traction across various industries due to its versatility. This method is especially popular in automotive, furniture, and construction sectors. The ability to create a durable, textured finish makes it an excellent choice for numerous applications. For example, automotive components often use this coating to resist wear and corrosion.

In the furniture industry, plastisol can enhance both aesthetics and functionality. It provides a soft, comfortable grip on handles or covers. However, not all products achieve the same visual appeal. Some finishes may show imperfections, affecting their marketability. In the construction sector, plastisol's robust nature helps in protecting tools and machinery, but the application process can be challenging. Maintaining consistent thickness is crucial, yet some operators struggle with this aspect.

While plastisol dip coating offers numerous benefits, it’s not without its flaws. Over time, some coatings may wear off or lose their luster. Users need to be aware of the potential for uneven coats, which can diminish the overall quality. Continuous improvements and careful monitoring during application can help mitigate these issues. By focusing on the right techniques, industries can take full advantage of this innovative coating solution.

Plastisol dip coating stands out in the coating industry for its outstanding durability. Unlike traditional methods like powder coating, plastisol creates a thicker layer, providing enhanced protection against corrosion. Data from the Coating Association indicates that plastisol can achieve a thickness of 12 to 25 mils. This level of thickness improves resistance to wear and tear, especially in challenging environments.

When comparing plastisol with other methods, variations appear in the application process. Unlike spray painting or powder coating, plastisol dip coating involves immersing parts in a heated polymer solution. This technique ensures uniform coverage with minimal overspray. However, it also raises concerns about consistency. The thickness can vary if not monitored properly.

Despite its strengths, plastisol dip coating isn't perfect. The curing process can lead to imperfections, such as bubbles or uneven surfaces. A report from the Finishing Institute highlights that even minor inconsistencies can compromise durability. Companies must weigh these factors against the benefits. Understanding these dynamics helps manufacturers make informed choices about coating options.

| Coating Method | Durability | Chemical Resistance | Cost-Effectiveness | Application Ease |

|---|---|---|---|---|

| Plastisol Dip Coating | High | Excellent | Moderate | Easy |

| Powder Coating | Very High | Good | High | Moderate |

| Liquid Paint | Moderate | Fair | Low | Difficult |

| Galvanization | High | Excellent | Very High | Complex |

| Anodizing | High | Good | Moderate | Moderate |