In the rapidly evolving landscape of manufacturing, molding items play a pivotal role in driving innovation. Industry expert John Smith, a leading figure in molding technologies, once stated, “The future of manufacturing lies in the precision and adaptability of molding items.” His words resonate as we delve into the trends shaping this sector for 2026.

The demand for high-quality molding items is increasing. Manufacturers are exploring new materials and techniques. Sustainability is a key focus. Companies are innovating to reduce waste while improving product quality. However, the challenge remains significant. Not all businesses can easily adopt these advancements. Many grapple with outdated machinery and practices that are not sustainable.

Emerging trends suggest a shift toward smart manufacturing solutions. Digital technology and automation are influencing the design of molding items. Companies must evaluate their strategies for growth carefully. They need to adapt to the ongoing changes or risk stagnation. As we look ahead, the molding items industry holds immense potential for breakthroughs but also requires a critical reflection on current practices.

In 2026, molding processes will undergo significant transformation. Emerging technologies are reshaping the landscape of manufacturing solutions. 3D printing is set to play a pivotal role. This technology enables rapid prototyping and complex designs that traditional methods cannot achieve. It also reduces waste, a critical factor for sustainable production.

Alongside 3D printing, artificial intelligence will enhance efficiency. Smart algorithms can optimize production schedules and improve quality control. However, reliance on AI may raise concerns about data security and job displacement. Human oversight remains crucial, as technology cannot replace human intuition entirely.

Moreover, biodegradable materials are gaining traction. These materials offer a sustainable alternative to plastics. However, their durability can sometimes be questionable. The industry must investigate long-term performance and usability. Balancing innovation with practicality will be a continuous challenge for manufacturers.

In recent years, sustainable materials have become a focal point in molding innovations. Manufacturers are increasingly exploring eco-friendly options. Biodegradable plastics, for example, are gaining traction. They offer a viable alternative to traditional petroleum-based materials. The quest for sustainability drives creativity in the industry.

Innovators are experimenting with materials like recycled composites. These can reduce waste and lower carbon footprints. However, the journey is not without challenges. Sourcing consistent quality from recycled materials can be tricky. There’s often a compromise between performance and sustainability. Some manufacturers struggle to meet customer expectations while maintaining eco-standards.

As this trend grows, companies must evaluate their processes. This includes assessing supply chains and production methods. Collaboration between industries might provide solutions. Nevertheless, ongoing experimentation is needed. The aspiration for a sustainable future fuels innovation in molding. Responses to these challenges could redefine manufacturing landscapes.

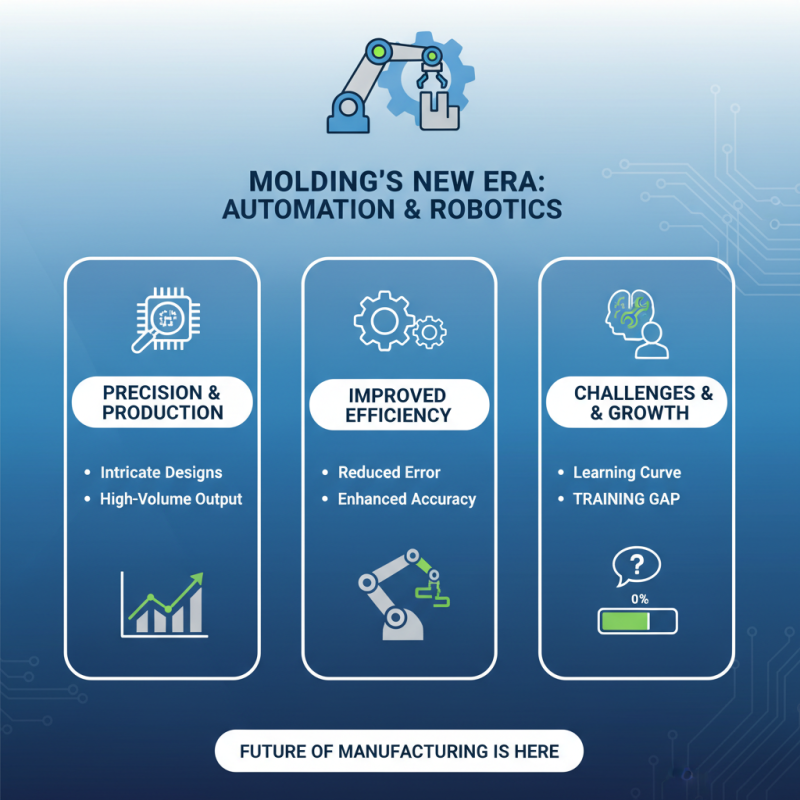

Automation and robotics are reshaping the molding industry. Advanced machines now handle intricate designs and high-volume production. These tools improve precision and reduce human error. However, there is a learning curve. Some operators may struggle with complex interfaces. Training programs need to catch up with technology.

The integration of robotics also comes with challenges. Workers fear job displacement. The balance between automation and human skill is crucial. Companies should focus on reskilling their workforce. Emphasizing collaboration can lead to innovative ideas. For example, combining manual craftsmanship with robotic efficiency might yield better results.

Examining this shift reveals both opportunities and pitfalls. Implementation takes time. Frequent upgrades to software and systems can overwhelm teams. Feedback loops must be established to address issues promptly. Only then can the potential of automation truly be realized in molding.

In 2026, the focus on customization and personalization in molding solutions will reshape the manufacturing landscape. According to industry reports, 85% of consumers prefer products that can be tailored to their needs. Businesses must adapt to this demand. Flexible manufacturing processes will become crucial to enable unique designs.

Customization goes beyond aesthetics. It involves functional enhancements as well. Data shows that personalized products can command a 20% higher price. However, implementing such solutions is not always smooth. There might be challenges with production efficiency. Companies need to invest in advanced technologies to overcome these issues.

Tips for manufacturers: Start with small-scale personalization tests to gauge consumer interest. Gather feedback to refine offerings. Embrace digital tools for rapid prototyping. This approach aids in minimizing waste and enhances innovation. Balancing customization with efficiency remains a critical task. The road ahead may be challenging, but the potential rewards are significant.

| Trend | Description | Expected Impact | Customization Level | Sustainability Index |

|---|---|---|---|---|

| 3D Printing Integration | Utilizing 3D printing technology for rapid prototyping and on-demand production. | High efficiency and reduced lead times. | High | Moderate |

| Smart Molding Processes | Implementation of IoT sensors in molding machinery for real-time monitoring. | Improved product quality and reduced waste. | Medium | High |

| Bio-material Usage | Use of biodegradable materials in the manufacturing process. | Enhanced brand reputation and market appeal. | High | Very High |

| Greater Personalization | Offering a wider range of customizable options for consumers. | Increased customer satisfaction and loyalty. | Very High | Low |

| Automation and Robotics | Incorporating automated systems in the molding process to reduce human error. | Cost savings and increased production speed. | Medium | Moderate |

The landscape of innovative molding items is rapidly evolving. Various market dynamics influence this transformation. A growing demand for sustainability drives manufacturers to adopt eco-friendly materials. Companies are rethinking their production processes to minimize waste. This shift not only appeals to environmentally conscious consumers but also enhances brand loyalty.

Technological advances play a crucial role in this growth. Automation and smart manufacturing improve efficiency. However, integrating new technologies can be challenging. Many manufacturers struggle with the initial costs and need for skilled labor. These barriers highlight the necessity for ongoing training and adaptability in workforce skills.

Consumer preferences are also changing. There is a notable shift toward personalization in products. As companies try to meet these diverse needs, they face pressure to innovate continuously. Balancing customization with production speed remains a key challenge. The pressure to stay ahead can lead to rushed decisions and oversights in quality control. This makes reflection on sustainability and quality even more important in the manufacturing process.